The ejection system is answerable for eliminating the formed part(s) from the shape after the shape opens. While this may appear to be a basic capacity, the intricacy of the ejection system can shift broadly relying upon the prerequisites of the embellishment application. Numerous issues must be considered including the requirement for various tomahawks of activation, the size and appropriation of the ejection powers, and others to get the automotive molds made in china. Prior to starting the examination and plan of the ejection system, an outline of its capacity is first given.

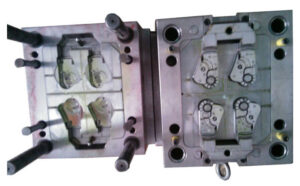

China industrial injection moulding manufacturers gives a side perspective on a form opening for the resulting ejection of the PC bezel. The ejector gathering (comprising of the ejector plate, ejector retainer plate, return pins, ejector pins, stop pins, and different parts) is housed between the back cinch plate, uphold plate, and rails.

Right now in the embellishment cycle, the shaped part has contracted onto the center side of the form and has been pulled from the form pit as the moving side of the form is withdrawn from the fixed side of the form. In almost no time, the trim machine will push the ejector take out bar against the ejector plate to incite the ejector gathering and strip the formed parts off the center. Right now, be that as it may, a freedom exists between the ejector take out bar and the ejector plate.

Plastic precision injection mould manufacturers china gives a side perspective on the form during the incitation of the discharge system. Preceding discharge, the ejection of the embellishment machine platens isolated the two shape parts to permit freedom for the discharge of the part. The machine at that point drives the ejector take out bar forward to connect with the back surface of the ejector plate. Since the machine can give a power to the take out bar a lot more noteworthy than the power with which the moldings have contracted onto the center, the whole ejector get together is constrained forward. The ejector pins come into contact with the formed part(s) and push the molding(s) off the center.

After the moldings are ejectioned out, the embellishment machine at that point withdraws the ejector take out bar as appeared in oem/odm automatives injection molding design factory. A freedom is then made between the front of the take out pole and the rear of the ejector plate, which permits the ejector get together to be reset to its unique situation for the following trim cycle.

There are a few different ways of resetting the ejector system, which will be talked about later. In any case, one regular strategy for restoring the ejector gathering is to just close the form as appeared in precision molds made in china. The front surface of the return pins will at that point contact the contradicting face of the A plate. The back surface of the return pins will at that point drive the ejector plate, ejector retainer plate, and all the ejector sticks in reverse as the form closes.

The plastic moldings will in general psychologist during cooling and will ordinarily stay on the shape centers upon the kickoff of the form. All things considered, systems are needed to push the parts off the shape during the ejection stage. While this essential capacity is handily perceived, there are a few related plan destinations that ought to be fulfilled in the plan of the ejection system.

This article is from http://www.automoldchina.com