Some cool plastic auto exterior mold images:

Bazile (33)

Image by Douglas R Witt

Now that Bazile is back in one piece, it’s time to do a little extra work in the back of the mask. The photos in this collection have taken place over the last three day… this is a time of waiting and working sections… it takes time for the mask to settle and dry, this work needs to be done somewhat slowly if you are to get a mask that isn’t warped out of shape. There are a few things that I do to keep it from deforming.

I use the original armature in this case it’s a plaster life cast of my teacher/actor friend Sean Daly. I put the mask back over the plaster armature to make sure it will not warp out of face shape.

I have found that Papier-mâching the inside of a mask must be done in stages… start with the middle features like the eyes nose and mouth… than Papier-mâché outward. Leave the rim of the mask as the last thing to mâché … this can be fast or slow… depending how large the mask is and how much interior work needs to be done… Bazile mask is still drying 72 hours later. It’s just starting to harden…

The reason it’s taken this long is because of two factors. It’s been raining a lot here and it’s made the apartment more humid than normal, the other and the main reason is because I used a TP Paste (the white stuff) to fill some of the large negative spaces like the nose, around the eyes, ears and bottom lip. The white stuff that you’re looking at is a mixture of all-purpose white glue and shredded bathroom tissue.

I use this TP Paste to fill in a few areas of the mask that I feel need some protection from wear and tear just in case it gets bumped while being used on stage. Once I have used the TP Paste to fill in the areas of the mask I want to straighten I will leave it to dry for 6 hours or more.

Warning: this mixture should be used sparingly because it takes a long while to dry, also if you use a ton of it will make the mask heavier hard to wear.

Even though I didn’t use very much of this Paste it will take three days plus to fully dry. I don’t use it very often, but it’s really a good thing to us to fill gaps. It’s like a mask maker’s auto body filler to smooth some uneven exterior lumps and it strengthens the mask, I felt this mask need it and what a great chance to show you 🙂 super mask making secretes

I do another six layers of Papier-mâché in the back of the masks. This will bulk up the mask a bit and give it some extra stability for frequent use on stage or using as a teaching mask. In these photos the first thing I did was use the TP fill and then let it sit to settle and dry in front of a fan for 16 hours. Then I cut out the ear holes, nostrils and trimmed the rim of the mask. Once I am happy with the timing I Papier-mâché six layers on the interior of the mask starting with the middle features in the mask and worked my way outward. I did the eye, ears, nose, chin and cheek area. Then I let it settles in front of the fan for another 8 hours. Once it was dry I finished the brows and forehead and Papier-mâché the rim of the mas with smaller ribbons of paper, this will seal the mask completely and keep it from possibly chipping for flaking apart from you’re face sweat and warm breath from regular use… it also makes it look nice.

Once all six layers of mâché are finish… put in front of the fan again and let it sit and dry again for at least 8 hours… there has been a lot of new work done on the mask and you will notice that it will be heavier… there is due to a lot of water added to the mask and it needs to dry out and settle… put it on the armature base you sculpted the mask on and leave it sit for a day or overnight.

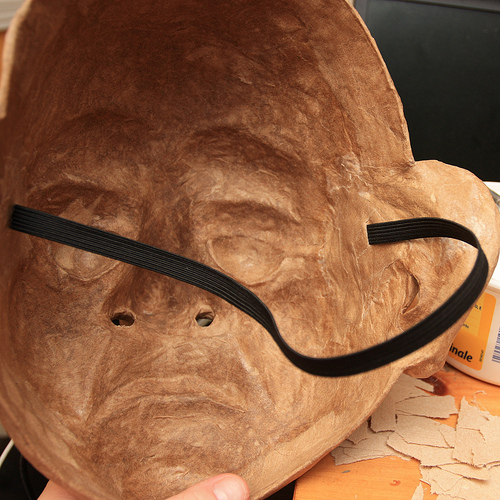

Now that the mask is dry… it’s time to add the fabric elastic head band, you can us any kind of head band suits your fancy or whatever turns you on… String, Ribbon, leather, Fabric elastic, etc… the way to attach them is basically the same although my method is not the only way… and you’re welcome to explore others.

For Bazile mask I am using a half inch black fabric elastic, you can pick it up at any place that sells fabric. I use black because it disappears on stage and it never looks dirty. I start off by measuring a length of fabric elastic from temple to temple. Coming around the crown of the back of the head and sitting behind the ears like a pair of sunglasses. I pull the elastic just a little snug (NOT TIGHT) you want the mask to fit a snuggly on your face… in the next set of photos I will be showing how to add foam rubber to the interior of the mask so it will sit comfortable on the face.

Once I have measured out my length of elastic set it aside and get a marker, put the mask on your face and find your temples on the inside of the mask. Once you have marked where the elastic is going to go, use a little dab of hot glue and glue the elastic in… and try the mask on. This may take a few tries so use a little hot glue until you find a comfortable fit. The mask may sit on your face a bit uncomfortable… it may be pressing into the corners of your eyes of sitting very snuggly to your face… that’s ok because that’s what the foam rubber is for.

The pain will show you where to put the foam… ha ha ha!

Once the mask fits snuggly it’s time to use a little more hot glue to anchor the fabric elastic into the mask, try to make the glue as flat as possible using the tip of the hot gun so that you’re not getting poked in the temples by hot glue lumps. Then Papier-mâché three more layers of paper over and around the fabric elastic and set the mask in front of a fan to dry for another 6 hours or so… it’s important to give the mask lots of drying time. The next steps are the sealing and painting and you want a nice dry mask to work on.

Person artist note to beginner mask makers:

The back of the mask is just as important as the front of the mask. Most people think it ends with taking the mask off the mold. But if you spend a few extra hours detailing and finishing the back of the mask you’re going to have a mask that will last longer and take a beating or hang on a wall without deforming over time.

It’s important to also reinforce the back and fill in some of the negative spaces… and add ventilation holes like nostrils and sometimes a small mouth slit. This will help the actor from overheating and cut down on sweating behind the mask. Some masks will fit very close to the face and subsequently create a vacuum effect that is like putting a plastic bag over your face. The ability to breath easily out of the mask is important it will help the actor forget there wearing a mask, also if all you have are eyeholes as venation entrance and exit the flow of air will dry out the performer’s eyes.

Please listen to this music while viewing this set of photos

youtu.be/9HtHEgINHO0