Some cool automotive parts mold images:

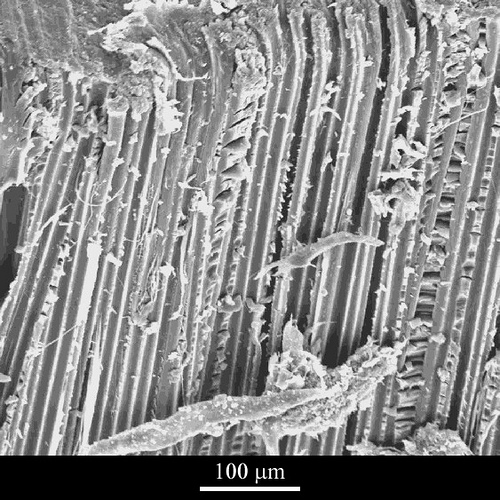

Kevlar fibre composite shear surface

Image by CORE-Materials

DoITPoMS, University of Cambridge

This is an image of the shear surface in a failed composite beam. ‘Hackles’ of matrix are clearly visible where shear has occurred within the matrix and it is also clear that shear has occurred across the fibre/matrix interface. The fibres are for the most part totally unscathed, though some mis-aligned fibres have become caught between the shear surfaces and ‘fibrillated’ by rolling and bending actions. It may be that this failure mechanism has been partly inhibited by poor fibre alignment since some off-axis fibres will reinforce the matrix in shear. It will have been promoted, however, by the extensive longitudinal voids.

System

Kevlar composite

Composition

Kevlar fibre, epoxy resin matrix

Reaction

Kevlar is a lyotropic liquid crystal polymer. This means that it can be readily processed in solution (in this case, sulphuric acid). It is annealed under tension to increase its elastic modulus

Processing

A crude Kevlar composite was made by laying out 40 tows of fibre, painting them with epoxy resin, compressing them in a mould, and curing them for five hours at 100-190 degrees C

Applications

Kevlar composites are used as a structural material in the aerospace and automotive industries, as well as in certain high-performance sporting equipment. They present exceptional stiffness and can be structurally optimised for particular load-bearing applications.

Sample preparation

The bar has been bent to failure in a three-point bending rig.

Technique

Scanning electron microscopy (SEM)

Contributor

J A Curran

Organisation

Department of Materials Science and Metallurgy, University of Cambridge

View micrograph in DoITPoMS website

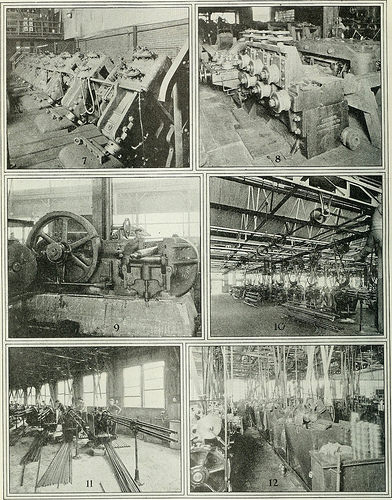

Image from page 935 of “Automotive industries” (1899)

Image by Internet Archive Book Images

Identifier: automotiveindust44phil

Title: Automotive industries

Year: 1899 (1890s)

Authors:

Subjects: Automobiles Aeronautics

Publisher: Philadelphia [etc.] Chilton [etc.]

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

(1) One of a battery of four modern electric furnaces with a daily capacity of slif/htly more than 150 tons. (2) Pouring■ ■■:,■■■■ •■/ into ,„,,,,/ moulds ,„ the Timhen steel will. ( ?,, 11 ,,,1 ran I ir press ami electric manipulator where inuots arepressed into blooms. (4) Twenty-two inch, three stand rolling mill and tilting tables where blooms are converted intorounds and squares with a size range of from 2 in. to 6% in. (5) Twelve inch, three-stand rolling mill where bars for rollsare converted into coils and small rods. (6) Piercing mill where bars are converted into seamless tubes. 914 AUTOMOTIVE INDUSTRIESTHE AUTOMOBILE April 28, 1921

Text Appearing After Image:

there pierced seamless tubes are automatically finished. (8) Straightening machine where finished traii/lttened. (9) Bulldozer for fabrication of formed seamless tubes. (10) Part of the screw machine nibesare fabricated on automatic screw machines into green cups and cones. (11) Four spindle roller fuhrictihit,/ much nies where rods tire fabricated al high speed into <• rarictij a) si cs o) rolls held to much tiling tolerances not in excess of .003 of an inch. (12) Another view of the screw machine department where large cups and cones made from forgings are machined on automatic screw machines. (7) Reducing millseamless tubes aredepartment win re tul April 28, 1921 AUTOMOTIVE INDUSTRIES THE AUTOMOBILE 915

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

4 remaining days of Major Project

Image by Matty Ring

The whiter coloured material is a mould made of silicon rubber, for the rims on my car. the yellow material is two part plastic.