A few nice auto molds made in china images I found:

Steven F. Udvar-Hazy Center: Hawker Hurricane Mk. IIC, with Northrop P-61C Black Widow in the background

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Hawker Hurricane Mk. IIC:

Hawker Chief Designer Sydney Camm’s Hurricane ranks with the most important aircraft designs in military aviation history. Designed in the late 1930s, when monoplanes were considered unstable and too radical to be successful, the Hurricane was the first British monoplane fighter and the first British fighter to exceed 483 kilometers (300 miles) per hour in level flight. Hurricane pilots fought the Luftwaffe and helped win the Battle of Britain in the summer of 1940.

This Mark IIC was built at the Langley factory, near what is now Heathrow Airport, early in 1944. It served as a training aircraft during the World War II in the Royal Air Force’s 41 OTU.

Donated by the Royal Air Force Museum

Manufacturer:

Hawker Aircraft Ltd.

Date:

1944

Country of Origin:

United Kingdom

Dimensions:

Wingspan: 12.2 m (40 ft)

Length: 9.8 m (32 ft 3 in)

Height: 4 m (13 ft)

Weight, empty: 2,624 kg (5,785 lb)

Weight, gross: 3,951 kg (8,710 lb)

Top speed:538 km/h (334 mph)

Engine:Rolls-Royce Merlin XX, liquid-cooled in-line V, 1,300 hp

Armament:four 20 mm Hispano cannons

Ordnance:two 250-lb or two 500-lb bombs or eight 3-in rockets

Materials:

Fuselage: Steel tube with aircraft spruce forms and fabric, aluminum cowling

Wings: Stressed Skin Aluminum

Horizontal Stablizer: Stress Skin aluminum

Rudder: fabric covered aluminum

Control Surfaces: fabric covered aluminum

Physical Description:

Hawker Hurricane Mk. IIC single seat, low wing monoplane ground attack fighter; enclosed cockpit; steel tube fuselage with aircraft spruce forms and fabric, aluminum cowling, stressed skin aluminum wings and horizontal stablizer, fabric covered aluminum rudder and control surfaces; grey green camoflage top surface paint scheme with dove grey underside; red and blue national roundel on upper wing surface and red, white, and blue roundel lower wing surface; red, white, blue, and yellow roundel fuselage sides; red, white and blue tail flash; Rolls-Royce Merlin XX, liquid cooled V-12, 1,280 horsepower engine; Armament, 4: 20mm Hispano cannons.

• • • • •

Quoting Smithsonian National Air and Space Museum | Northrop P-61C Black Widow:

The P-61 Black Widow was the first U.S. aircraft designed to locate and destroy enemy aircraft at night and in bad weather, a feat made possible by the use of on-board radar. The prototype first flew in 1942. P-61 combat operations began just after D-Day, June 6, 1944, when Black Widows flew deep into German airspace, bombing and strafing trains and road traffic. Operations in the Pacific began at about the same time. By the end of World War II, Black Widows had seen combat in every theater and had destroyed 127 enemy aircraft and 18 German V-1 buzz bombs.

The Museum’s Black Widow, a P-61C-1-NO, was delivered to the Army Air Forces in July 1945. It participated in cold-weather tests, high-altitude drop tests, and in the National Thunderstorm Project, for which the top turret was removed to make room for thunderstorm monitoring equipment.

Transferred from the United States Air Force.

Manufacturer:

Northrop Aircraft Inc.

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 450 x 1500cm, 10637kg, 2000cm (14ft 9 3/16in. x 49ft 2 9/16in., 23450.3lb., 65ft 7 3/8in.)

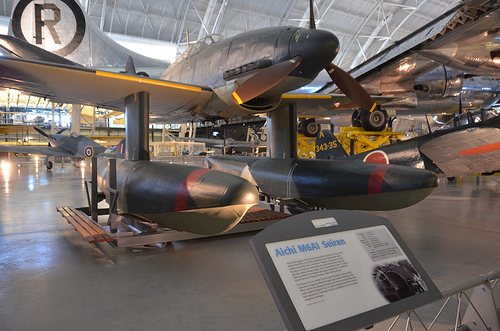

Steven F. Udvar-Hazy Center: Aichi M6A1 Seiran

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Aichi M6A1 Seiran (Clear Sky Storm):

Aichi chief engineer, Toshio Ozaki, designed the M6A1 Seiran to fulfill the requirement for a bomber that could operate exclusively from a submarine. Japanese war planners devised the idea as a means for striking directly at the United States mainland and other important strategic targets, like the Panama Canal, that lay thousands of kilometers from Japan. To support Seiran operations, the Japanese developed a fleet of submarine aircraft carriers to bring the aircraft within striking distance. No Seiran ever saw combat, but the Seiran/submarine weapons system represents an ingenious blend of aviation and marine technology.

This M6A1 was the last airframe built (serial number 28) and the only surviving example of the Seiran in the world. Imperial Japanese Navy Lt. Kazuo Akatsuka ferried this Seiran from Fukuyama to Yokosuka where he surrendered it to an American occupation contingent.

Transferred from the United States Navy.

Manufacturer:

Aichi Aircraft Company (Aichi Kokuki KK)

Date:

1945

Country of Origin:

Japan

Dimensions:

Overall: 460 x 1160cm, 3310kg, 1230cm (15ft 1 1/8in. x 38ft 11/16in., 7297.2lb., 40ft 4 1/4in.)

Physical Description:

Wings rotated back, folded back to lie flat against the fuselage. 2/3 of each side of the horizontal stabilizer also folded down, likewise the tip of the vertical stabilizer.

Steven F. Udvar-Hazy Center: Northrop P-61C Black Widow

Image by Chris Devers

Compare & contrast:

Northrop P-61C Black widow:

* Front view

* Above view

Star Wars ARC-170 Fighter:

* Official page

* Wikia

* Wikipedia

* Toy review

I put it to you that they’re the SAME THING.

* twin engines

* double-cockpit in front

* gunner’s cockpit in back

* broad wing coming out from the middle

***************

Quoting Smithsonian National Air and Space Museum | Northrop P-61C Black Widow:

The P-61 Black Widow was the first U.S. aircraft designed to locate and destroy enemy aircraft at night and in bad weather, a feat made possible by the use of on-board radar. The prototype first flew in 1942. P-61 combat operations began just after D-Day, June 6, 1944, when Black Widows flew deep into German airspace, bombing and strafing trains and road traffic. Operations in the Pacific began at about the same time. By the end of World War II, Black Widows had seen combat in every theater and had destroyed 127 enemy aircraft and 18 German V-1 buzz bombs.

The Museum’s Black Widow, a P-61C-1-NO, was delivered to the Army Air Forces in July 1945. It participated in cold-weather tests, high-altitude drop tests, and in the National Thunderstorm Project, for which the top turret was removed to make room for thunderstorm monitoring equipment.

Transferred from the United States Air Force.

Manufacturer:

Northrop Aircraft Inc.

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 450 x 1500cm, 10637kg, 2000cm (14ft 9 3/16in. x 49ft 2 9/16in., 23450.3lb., 65ft 7 3/8in.)