Check out these automobile plastic parts made in china pictures:

Steven F. Udvar-Hazy Center: Photomontage of Overview of the south hangar, such as B-29 “Enola Gay” and Concorde

Image by Chris Devers

Check out these automobile plastic parts made in china pictures:

Steven F. Udvar-Hazy Center: Photomontage of Overview of the south hangar, such as B-29 “Enola Gay” and Concorde

Image by Chris Devers

Verify out these plastic auto lamp mould maker pictures:

DESCRIPTION: Now days there is large demand for plastic auto trim molding in the nearly all automobile industries. The makers primarily choose plastic as it is light weight which can be very easily employed in designing the car which eventually leads to saving a huge amount of power. This increases to the demand and popularity of the auto mold manufacturers. The plastic manufactured are obtainable in distinct designs and pattern which can be easily utilised for various molds and these molds are employed in various automobile industries.

AUTO MOLDS Attributes ARE AS FOLLOWS:

*Flexibility and reliability in design and style:

It is easy to locate a auto plastic trim mold marker in today’s marketplace. The market is complete of makers that manufacture different varieties of mold obtaining various shapes and style. Plastic is 1 of the major components that manufacture prefers for different molds design due to the fact of its light weight and flexibility and reliability. It can be effortlessly molded in distinct specified styles and shapes. Plastics give great chance for every sector particularly in automobile industries.

*Distinct Auto Components being manufactured:

An auto mold manufacturer is generally located to be involved with large numbers of companies that manufactures automobile in the market place. Diverse kinds of molds getting distinct shape and size are used for creating different car parts. These range from automobile interior parts, handle panel, breakingsystem, shockabsorber, spareparts, controlpanel, grilles and triangle and even numerous more components .These various components shape and style depends upon the mold becoming utilized. To satisfy the distinct user ends and needs the automobile manufacturer go for the design and style of the cars with the assist of these molds.

*Numerous professionals are involved:

It is not an easy process to make molds. A lot of difficulties are involved in making mold indeed machines are accessible which helps in producing the mold. Several authorities and skilled and engineers are involved in generating the completed products. The efforts of the complete group involved helps out in creating the solution which is of very good quality and sturdy. Several things are taken into the consideration whilst creating out the design and style and shape of the mold.

As a result, an auto plastic trim mold maker is in demand now days. Nonetheless, in the tough scenarios there is lot of competitors in the market place so it is essential for the producers to make the content material or finished product with a good quality. If manufacture compromise on top quality than he has to compromise on the profit that he can obtain effortlessly. Considering that a lot of products are becoming produced in the single cycle so the manufacture can simply get a huge quantity of profit on the items. The contribution of auto trim mold maker in the market can not be ignored ever in lifetime.

Associated Auto Molds Manufacturers Articles

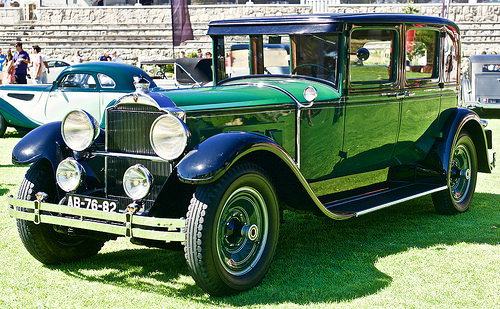

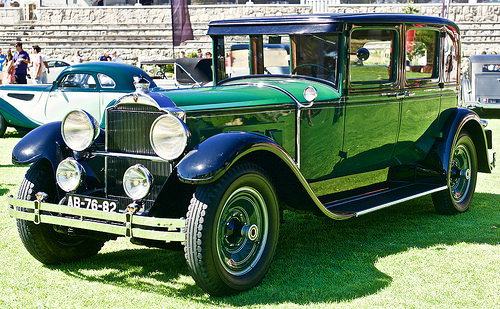

Some cool automotive interior mold manufacturers images:

65 Ford Mustang GT Retractable Hardtop

Image by DVS1mn

Willmar Car Club 2014 Kandi Mall Display

www.flickr.com/photos/greggjerdingen/collections/72157640…

This article originally appeared in the October, 2005 issue of Hemmings Classic Car.

There exist no new ideas.

Whatever variation of synapse connections you’ve managed to form in a method new to you has almost surely taken place in the minds of men years, generations, or centuries before. No offense, that’s just what happens when billions of people inhabit one planet over several millennia. Watch a television show or listen to a song on the radio and you’ll swear you’ve seen that plot or heard that lyric before.

Another prime example–convertible hardtops.

The Lexus SC430 offers both the safety and comfort of a hardtop over your head and the thrill of open-top motoring, as it has since 2000. But the Mercedes-Benz SLK offered the same option back in 1996. The Mitsubishi 3000GT introduced the bodystyle two years prior.

Automakers on this side of the pond have only brought retractables back to showrooms recently, with the appearance of the Pontiac G6 for the 2006 model year, the Cadillac XLR in 2003 and the Chevrolet SSR about the same time.

Pie-in-the-sky dream cars have used the feature as a gimmick for years. Benjamin B. Ellerbeck, of Salt Lake City, Utah, patented a retractable metal roof in 1922, then fitted it to a 1919 Hudson, but he couldn’t find a manufacturer to bring his dream to life. Coachbuilders and infinitesimal-run versions of production cars have employed it as far back as 1933, on the Hotchkiss Eclipse by Pourtout.

Right about in the middle of it all came Ben J. Smith and his desire to see a retractable hardtop fitted to a Ford Mustang.

Smith, 82, can be likened to a latter-day Ellerbeck, if only in their tenacity in pursuing this common idea. Ellerbeck, after building his Hudson, pursued a one-man publicity campaign for the idea in the automotive journals of the day. He tried unsuccessfully to attract Packard as a builder and claimed he took several orders, but Ellerbeck’s idea seemed not to earn him much fame nor money as he continued his publicity march through the 1930s.

Smith, however, stood a better chance for success. A Detroit native, he went to Ford where he started as a wood pattern maker in 1940. He said he remained on deferment until an acquaintance reported him to the draft board, so rather than face Uncle Sam’s wrath, he enlisted in the Navy in 1944 for 17 months. Smith returned to Ford for its Light Ford program; then, in 1949, moved to Nash and later took a job with General Motors’ Fisher Body Division, engineering hardtops and convertibles.

In about the same time span, Ford Advanced Studio designer Gil Spear penned the retractable hardtop idea. Whether he knew of Ellerbeck’s efforts has never been mentioned, but his idea resembled Ellerbeck’s–a hardtop that simply slid down over the trunk lid. Nothing to stow away, no complex mechanisms. (Dick Teague, the legendary AMC stylist, penned a small retractable in 1946 for Kaiser-Frazer that also used the same basic principle, though the concept never progressed beyond paper.)

Spear’s first drawing emerged in October 1948, according to Jim and Cheryl Farrell’s book, Ford Design Department Concepts and Showcars, 1932-1961. But the idea didn’t re-emerge until it appeared on Ford’s 1953 Syrtis show car. By then, Spear had refined the idea to drop the hardtop under the trunk lid. The Syrtis ultimately met the business end of a sledgehammer multiple times, but Spear had convinced William Clay Ford, Ford’s general manager of Special Products Operations, that the Continental Mark II project–which got the go-ahead in 1953–had to include a retractable hardtop.

Harley Copp, the chief engineer for the Mark II project, brought his brother-in-law, John Hollowell, into the project. Hollowell, who worked with Ben Smith on the Light Ford project, in turn hired Smith away from GM. With a budget of .19 million and 18 months, Hollowell and Smith finished MP#5, a Mark II mule fitted with a fully operational powered convertible hardtop. The car generated great applause, but the project’s leaders sacked the idea when they realized that Ford could only build the Mark II in one bodystyle.

To recoup the investment, Ford had Smith integrate the concept into the 1957 Ford, hoping the additional million invested in modifying the Fairlane body and in tooling would amortize over an anticipated larger run. The Ford retractable hardtop, introduced in mid-1957, and called the Skyliner in 1958-59, used essentially the same system developed for the Mark II. Smith had to extend the Fairlane’s rear sheetmetal by three inches, shorten the hardtop 3.75 inches and relocate the gas tank, but he finished the design work right at the December 1956 deadline.

Ford sold nearly 48,400 Skyliners over the car’s three-year run–good enough to give Ford bragging rights as the first to mass-produce such a design. But the sales didn’t justify the investment, so GM and Chrysler decided not to compete.

Smith, though, never forgot the idea. Maybe because he drove MP#5 on the streets of Detroit for two years, until he came back from vacation to find it scrapped. Maybe because he later read about the Peugeot Eclipses of the 1930s. Whatever inspiration he took, it lay dormant in his mind for the better part of a decade.

From 1959 to 1964, Smith served as chief engineer for Ford of Argentina. In 1964, he became executive engineer for Ford’s Commonwealth zones, and a year later William Clay Ford tapped him to head up advanced package engineering in Detroit.

By this time, the Mustang had become Ford’s darling. Demand continually outstripped production, and its first-year sales broke the record set just a few years earlier by the Falcon. Ford product planners really had just the two models to offer to begin with, so they scrambled for more.

"We had worked up such a head of steam on the first Mustang that we were already looking for variations on the theme," Gene Bordinat, Ford’s styling chief at the time, said in Gary Witzenburg’s Mustang: The Complete History of America’s Pioneer Ponycar.

For that reason, Bordinat’s Mustang styling group whipped up the fastback bodystyle and Lee Iacocca approved it the minute he saw it. Though designers played around with prototype removable hardtops and rejected the idea before the Mustang’s April 1964 introduction, a dealer-installed folding sunroof made the options list and some dealers at the time offered aftermarket removable hardtops for the convertibles.

So what better time to pitch a convertible hardtop for the Mustang?

Rather than reprise the Mark II/Skyliner design, Smith had a simpler idea. Instead of adding the 13 switches, 10 solenoids, nine circuit breakers, five motors and 610 feet of wire that powered the Skyliner’s retractable top, Smith wanted the Mustang’s top completely manual. And instead of dropping the roof as one piece into the trunk–something the 1957 Fairlane’s styling permitted–Smith designed a clamshell-style roof that worked better with the Mustang’s long-hood, short-deck styling.

To the best of our research, clamshell design appeared just twice prior–on the 1948 Playboy and on a car designed by J.R.V. Dolphin of Buckingham, England, the same year. We’ve found little additional information about Dolphin’s design, other than that it was installed on an Allard chassis, and the Playboy, of which 97 total were made, used the top section as a rigid boot directly behind the seat. Smith’s design, however, placed the entire top under the trunklid, leaving the rear seat open for passengers.

Smith actually started working on his idea in mid-1965. He had a discretionary budget of about 0,000 and said he spent between ,000 and ,000 developing a retractable hardtop for the Mustang with the help of his assistant, Roy Butler, who followed Smith to Ford from GM, and of Ford designer Dick Papps. Before long, he decided to approach upper management with the project.

"We finally got authority (from Ford) for 5,000, but it could have been a quarter-million dollars, I simply don’t remember," Smith said. "So I let a build contract out to John Hollowell. He left Ford and started his own engineering company (in 1962), so he did some manufacturing himself.

"I ordered a 1965 coupe special off the production line–it had all the bells and whistles and the biggest engine you could get at the time. I put double torque boxes in the front and added on to the rocker panel to strengthen the chassis for when we cut the roof off. Anything I designed for that was an add-on weld. I could put the front right wheel on a curb and the back left wheel on a block and open the doors without losing any structural integrity.

"I increased the length of the car about two and a half inches, just in the rear overhang, so I could fit the roof in the trunk," Smith said. "The wheelbase stayed the same; I just extended the sheetmetal back. Well, that required new taillamps and a new rear bumper. And the decklid, I had to turn it around, so it could open from the front. Yes, the decklid styling came from my Lincoln styling days, but we also needed the space in there to stow the top when it was down."

In addition, the gas tank and filler moved behind the rear seat, just as it had on MP#5. Smith even envisioned four additional tops for the project: one of brushed aluminum, one of stainless steel, one vinyl-covered fiberglass top and one stamped-steel top. He said Hollowell could only fabricate the latter two, but even those remained on the sidelines, not a part of the car’s overall presentation.

"The whole project was a quickie," Smith said. "From concept, we had the car built in seven months. It was completed in the spring of 1966. We didn’t have to get any staff engineering approval, so that cut through all the red tape."

Smith said he doesn’t remember whether Iacocca saw the car, but he did present it to Henry Ford II and Don Petersen, then head of product planning. "We never showed the car in public, but I remember we did take it to Cincinnati to do some market research next to then-current convertibles," Smith said. "It had raving reviews. People said they’d rather have it than a convertible, and nobody said anything about it not being mechanized.

"So it was all ready to go, but Petersen, he wanted it mechanized, and he knew we could do it, so he went out and took another study. He asked, ‘Do you want it manual or mechanized?’ Something like 92 percent of the people said mechanized. Well, that was cheating –you know what the answer to that question’s going to be. I don’t even know if that product planning showing even took place."

Nevertheless, Ford assigned Smith with the task of mechanizing the retractable Mustang.

"I made the top counterbalanced, so it wasn’t necessary to power it," Smith said. "It was so simple to do it. The maximum lifting weight was around 10 pounds. I had my five-foot-two secretary come out to operate it, and she had no problem putting it up and down."

Smith and Butler took another four months to design a power-operated top, but at the end, told upper management Ford couldn’t reasonably add the power mechanisms to the retractable hardtop.

Smith said he sent off some strongly worded letters to Petersen and his product planning people, to Bob McNamara and to several others in Ford management, telling them the company was headed in the wrong direction by axing his project. That one prototype remained, though, so Smith drove it around Dearborn for several months as a personal car.

"I remember the back seats folded down, so I could use the deck compartment for hauling luggage," Smith said. "I once loaded a good amount of lumber back there too."

But as with the Mark II mule, Smith returned from a vacation in late fall of 1966 to find the Mustang gone. Smith said he never saw the scrap order for the retractable Mustang.

"When I saw that it was gone, I went into styling, where they let me see the paperwork for scrapping cars," Smith said. "They told me, ‘Ben, you don’t want to follow that one.’ So I’m sure it went to some higher-up."

Rumors also persist about that original retractable. Smith said he heard once that someone had spotted a retractable Mustang in Oklahoma City, but he never could verify that. Another rumor places the car in the basement of Ford world headquarters.

Shortly after, Smith went to Ford of Brazil as product director. Then in February of 1968, he decided to take a leave of absence–essentially an early retirement–from Ford, on the condition that he wouldn’t work for GM or Chrysler.

But he never forgot that retractable Mustang. Nor did his kids. Smith’s son, David, said he still has a framed photograph of himself as a boy standing next to that prototype. Sometime in the late 1980s, Smith wrote an article about the Mustang for the Skyliner club’s book on retractables, which spurred some interest in the car.

"For years, my kids asked why I didn’t do another one," Smith said. "So I started to do it as a lark."

In September or October of 1993, while living in Arizona, Ben Smith bought a used 1966 Mustang coupe. At around the same time, David Smith, living in Connecticut, bought a similar 1965 coupe. Ben traced the outline of the Mustang on his garage wall and sketched his ideas for another retractable hardtop, following the original design, but keeping the car’s overall length, gas tank, filler location, taillamps, passenger interior and rear bumper intact.

He took cardboard templates down to a local fiberglass shop and, by December 1993, had the first sets of molds completed and ready for installation by Magnolia Auto Body in Santee, California. He reprised his torque boxes and chassis strengtheners from the original prototype.

"I didn’t use any drawings," Ben said. "We just made a top, cut it in two, then did all the modeling of the roof panels and trunklid."

David, who runs a body shop, said Ben flew the molds to him in January of 1994, enabling him to finish the work on his 1965 in his own shop.

"We wanted to use the tops Dad made for the original," David said. "So we called up the manufacturer that built those tops, thinking they kept them stashed in the rafters, but they were gone.

"By April 10, we had designed the hardtop, made it, and put it on two cars. The 1966, we called Prototype One, it was red with a buckskin interior and a beige top. We showed that one at Knott’s Berry Farm in California the weekend of the 13th. The 1965 was Prototype Two, it was powder blue with a blue top. We showed it at the national Mustang show in Charlotte, North Carolina, the same weekend."

At the Charlotte show, David met Ron Bramlett, the owner of Mustangs Plus in Stockton, California. That meeting led not only to Mustangs Plus’s chassis strengthening kit, using all the pieces developed by Ben and manufactured by David, but also to Mustangs Plus retailing a retractable Mustang kit. Mustangs Plus built one of the earliest of the kits and continues to use that car in their promotions today.

A third prototype followed–this one in gunmetal gray–built for Ben’s other son, Ben A. Smith. Around the same time, Ben decided to form a limited partnership, Retractables Unlimited, to produce and assist with the installation of retractable hardtop kits. Ben said the effort lasted about two years, with total production of between 35 and 50 kits, all signed and numbered. David constructed about eight to 10 of the kits in his shop, Coastal Collision of New London, Connecticut, and sold them as complete cars. His father never sold any complete cars, and Ben A. Smith sold two complete cars, including Prototype Three.

Whatever the number, Ben said he never made any money on the venture simply because he didn’t have the time to devote to marketing. He bought out his investors, dissolved the partnership and shipped his entire inventory to David.

Like many people who first encounter the Mustangs, Rae Johnston, of Goshen, Indiana, had never heard of the retractable hardtop. But while in Phoenix about seven years ago on a business trip, he met Ben Smith and got to see and purchase No. 8, our driveReport car, painted maroon with a white top, just like his 19641Ú2 convertible.

"I liked the uniqueness of it," Johnston said. "Sure, it’s not automatic, but it’s still one-tenth of the work of a normal convertible. It has torsion bars, so once you pick it up, it goes back and forth without any effort.

"This one came with factory air conditioning and the two-barrel, single-exhaust 289, so my wife likes it, though I usually like cars with a little more zip. But because of the frame rails (chassis strengthening kit), the retractable handles better than a regular Mustang."

Ben Smith said he likes seeing the number of modern cars adopting the retractable hardtop concept–it’s a sort of vindication for him. In fact, he claims he sketched a clamshell-type convertible hardtop for the chief engineer of Mercedes over dinner four years before the introduction of the SLK. However, he wonders how many modern interpretations will actually last.

On hearing news that an aftermarket company is considering developing a retractable hardtop for the new, retro-styled Mustang, Smith said he believes it’s doable.

"I know this is a push-button age, but I’ll disagree with any complexity," he said. "It could be very easy, like mine was, and I think something very simple would turn into a classic."

1970′s inventions that changed our way of life

Image by brizzle born and bred

Technology, Fashion and Toys played an increasingly important part in people’s lives in the 70s.

Ceefax: 1974

Launched in 1974, Ceefax went live with 30 pages and was the first teletext service in the world. Started as an experiment for the deaf, Ceefax developed into an instant news, sports and information service for millions of armchair surfers.

Colour Television Sets

Introduced on BBC 2 for Wimbledon coverage on July 1, 1967. The launch of the BBC 2 "full" color service took place on December 2, 1967. Some British TV programs, however, had been produced in color even before the introduction of color television in 1967, for the purpose of sales to American, Canadian, and Filipino networks. BBC 1 and ITV started color transmissions November 15, 1969.

The first colour sets became available in Britain in 1967, when BBC2 started broadcasting in colour. (Note BBC1 and ITV didn’t go colour until 1969.)

A typical 22" colour set would have cost £300 in 1967, or around £3000 in today’s money – equivalent to a top of the line 50+ inch LCD or LED HDTV set.

Britain’s oldest colour telly ‘still going strong’ 42 years on, says 69-year-old owner

www.dailymail.co.uk/news/article-1328760/Britains-oldest-…

Home Music Centre

The ultimate piece of kit that most people wanted in the mid 70s was a "Music Centre". This was a record player, cassette tape recorder and radio combined. Dynatron made one of the first, the HFC38 Stereo/Audio Cassette System, launched in 1972. This was a high priced luxury item at the time.

Dial Telephone

The 746 telephone was the British GPO’s main telephone for the 1970s. It was the phone most people had in the 70s and it is phone you will remember from that decade.

In the 70s, the home telephone was still a luxury in the UK. The General Post Office (GPO) had a monopoly on telephone services and anyone who wanted a phone needed to rent one from the GPO.

Although still a state run monopoly, the telephone service was more modern in the 70s. The old fashioned lettered exchanges disappeared in the late 60s and the new phones were equipped for the strangely termed ‘all figure numbering’. Customers had a choice of three phones: the 746, the smaller 776 Compact Telephone and the modern looking Trimphone.

The 746 telephone was an upgraded version of the 706 phone or ‘Modern Telephone’ that the GPO introduced to customers in the early 60s.

It introduced a few practical improvements. Firstly there was a clear plastic dial showing only numbers. The case had an integral carry handle and the phone came in a more modern plastic. It was also lighter and had improved circuitry.

Electronic Calculator

The first pocket calculators came onto the market towards the end of 1970. In the early 70s they were an expensive status symbol. By the middle of the decade, people used them to add up the weekly shopping at the supermarket. As pocket calculators moved from executive’s briefcases to school children’s satchels, there was controversy over whether children could still do sums.

Jack Kilby of Texas Instruments developed the integrated circuit technology that made the pocket calculator possible in the sixties. TI’s first prototype hand held calculator, the Cal Tech, demonstrated the potential of the new device. However, as with the transistor radio, Japanese firms quickly exploited the technology. The first portable, as opposed to pocket sized, calculator was the Sharp QT-8B. A year later pocket sized models were available from Bowmar (USA), Sharp, Busicom (Japan) and Sanyo.

Very quickly a host of manufacturers entered into the growing pocket calculator market. Texas Instruments launched their own model, the TI-2500 Datamath, in 1972.

Electronic games

Electronic games, such as MB Simon and Adman Grandstand, went on sale in the UK in the second half of the 70s. This was the time when people got their first taste of the digital lifestyle we enjoy today. A few years earlier, the first calculators and LED digital watches were marketed. Now manufacturers too adopted the same circuitry for play, and the age of electronic games began.

This revolution was reflected in the small screen when ITV’s George and Mildred’s neighbours bought a Grandstand game for Christmas. There were also concerns that TV audiences would drop, with more people using their TVs to play video games instead. Granada TV’s report "Who’ll be watching Coronation Street in 1984?" expressed concerns their advertising revenue might be at risk.

The grand daddy of all the computer games was the Magnavox Odyssey, which was launched in 1972. It introduced the public to a familiar, but primitive, electronic bat and ball game. Magnavox Odyssey was quite sophisticated; it offered range of different games, some of which required props. However, it was more of US than an UK phenomenon.

Electronic chess games also appeared in the mid seventies, but the game that first captured the public’s imagination in the UK was the Adman Grandstand.

Freezers

In the 70s, freezer ownership increased dramatically. Freezers and frozen food were available in the 60s, but sales of freezers took off in the 70s. In 1970 around 100,000 were sold, which was three times as many as in 1967. By 1974, one in ten households had a freezer.

Food processors

A food processor added a choice of blades and attachments to a standard blender. The Magimix from the 70s was the first UK example.

Microwave ovens

The microwave oven was invented by Percy Spencer in the late 40s. Initially, microwave ovens were only used by catering establishments. Oxford University physicist, Professor Nicholas Kurti gave a dramatic demonstration of microwave cooking with his reverse baked Alaska, or frozen Florida, which had ice cream on the outside and hot filling on the inside. He first demonstrated this dessert in 1969, showing how microwaves easily passed through ice, causing little heat, but the filling made from brandy and marmalade absorbed them and heated up more quickly.

Microwave ovens were not available in Britain until the end of the 70s, even then they did not catch on that quickly. The first ‘Which’ report on microwave ovens was written in 1979. There were concerns about what would happen if the microwaves escaped and confusion over whether the ovens were radioactive. For most people though, they were simply too expensive.

By 1979, there were a variety of microwaves on the market, priced between 150 and 400. [500 to 1400 in today’s money]. Models with a separate convection heating element were even more expensive. Both traditional oven makers, Creda and Belling and electronics giants Philips, Hitachi, Sanyo, Sharp and Toshiba, made microwave ovens in the 70s.

For most people in the UK the microwave revolution did not begin until well into the 80s. Jimmy Tarbuck’s advertisements for Sharp microwaves helped promote microwave cooking in the UK in the early 80s.

Teasmaid

As part of our renewed appreciation of all things 70s, the teasmade is back in fashion. After years in the naff cupboard, John and Norma Major owned one, it is now hip to own a teasmade.

The teasmade was a luxury item in the 70s household. Although primitive devices for automatically making tea were available since Victorian times and leading manufacturer Goblin made teasmades since the thirties, they were never considered essentials.

Most teasmades (sometimes incorrectly spelled ‘teasmaid’) comprised a teapot, kettle and clock. To prepare the teasmade ready for use tea, or teabags, fashionable in the 70s, were added to the pot and water into the kettle and then the alarm was set for the time you wanted to wake up to enjoy your freshly made pot of tea. About ten minutes before the alarm went off, the kettle boiled the water, which bubbled through a spout into the teapot. If you forgot to put the spout into the teapot some 70s models poured boiling water on to whatever the teasmade was stood on. Once the tea was brewed, the alarm sounded to wake you up, if the mechanism had not already woken you.

In 1971 there were only three manufacturers of teamade: Goblin, Ecko and Russell Hobbs. The Goblin model shown here cost £27.18 (£265 in today’s money). It is no wonder that the teasmade was a luxury.

Tea bags

Tea bags were new in the 70s. Well not exactly new, they had been used in the USA since the 20s. Tetley had tried introducing them to the UK twice, once in the 30s and again in the 50s, but they were seen as a bit of a joke. In the 70s though, sales of tea bags took off. It’s hard to explain why, they were more expensive and rarely used in the way originally intended – to remove the tea from the pot once it was brewed. It may have been something to do with convenience. We could throw our tea strainers away. Now tea bags are almost universal – so they must have been a good idea after all!

Continental quilts

Until the 70s, most people in the UK made up beds with sheets and blankets. In the early 70s the bedroom revolution was the continental quilt or duvet. Names such as "Slumberland Fjord" and "Banlite Continental" left no doubt as to the origin. Mostly they were filled with down or duck feathers. Synthetic fillings were more common in Europe, but became available in the UK. People quickly took to them as they were more convenient.

Flares and platform soles

Two trends defined the 70s in a fashion sense: flared trousers and platform soles. Flares were derived from the hippy fashion for loon pants of the late 60s. They were worn by men and women. The flare was from the knee and reached exaggerated proportions in the middle years of the 70s. The trousers were often hipsters, sitting on the hips rather than the waist, and tight fitting.

The combination of flares and denim made flared jeans the fashion phenomenon of the decade.

Platform soles were mainly worn by women and more fashionable men. There were health warnings about damage that could be caused to the back in later life, but the fashion did not last long enough for that to have an effect. There was an element of thirties retro in the style of some of the shoes, which echoed the thirties’ love of two-tone or co-respondent black and cream or brown and cream colours. Bright colours also gave the shoes more of a space age look.

Raleigh Chopper

The Raleigh Chopper brought the style of Easy Rider to the backstreets of Britain in the 70s. It took the UK youth bike market by storm and probably saved Raleigh from financial disaster. The Chopper was a distinctly different bike for young people and was a first choice Christmas present. However, the Chopper attracted criticism for some aspects of its safety. The Chopper became distinctly unfashionable in the 80s, when BMX became the latest craze.

Klackers

Klackers comprised two acrylic balls, often brightly coloured, on a string with a small handle in the middle. It was a playground craze that swept Britain and America in the early 70s. The idea was to move the handle up and down to make the balls click together. The really skilled could make the Klackers meet at the top and bottom of a circle; it required practice. They made a noise when they clacked together, hence the name.

Klackers were also marketed as Ker-knockers, Clackers and Klickies.

Whilst children loved the Klackers, or Ker-knock-ers, parents and teachers were concerned about the safety aspects. They could cause bruised hands and arms and the balls could shatter into dangerously sharp shards of plastic. Some schools banned them from the playground. Like most crazes, Klackers disappeared as quickly as they appeared.

Invicta Mastermind game

The Invicta Mastermind game was a huge seller in the 70s. In spite of the name, it had no connection with the Mastermind television programme originally hosted by Magnus Magnussen, although many people bought the game thinking it did.

The game was invented by Israeli postmaster and telecommunications expert, Mordecai Meirowitz. He initially found it difficult to get a manufacturer to take on his idea, but eventually managed to persuade small UK games maker, Invicta to make it.

The game went on sale in the early 70s and was a huge success. The box depicting a bearded man and woman in Asian dress carried an air of mysteriousness about it, suggesting supreme intelligence was needed to play the game.

Indeed Mastermind was taken seriously by the academic world. In 1977, Donald Knuth, the American computer scientist responsible for some learned texts in the world of computing, published a formula that guaranteed a correct guess in five goes.

Mastermind was also recognised by the toy industry. In 1973 Invtica was awarded ‘Game of the Year’ for Mastermind. Look out for pre-1973 versions that do not have the ‘Game of the Year’ award on the box.

Fondue set

Fondue originated in Switzerland and the classic fondue is always made with Swiss cheeses: Emmenthal and Gruyère. The word ‘fondue’ is derived from the French word, ‘fondre’, which means to blend.

By 1960, Marguerite Patten claimed the fondue was becoming popular. Her ‘Cookery in Colour’ featured fondue recipes with a decidedly English twist: ‘Cheddar Fondue’ and ‘Tomato Fondue’, as well as the classic ‘Gruyère’.

It was in the seventies that fondue parties really took off in the UK. Originally a reminder of a Swiss dish tried on a skiing holiday, fondue parties soon became the up-to-the minute thing to do; but by the 80s, it was decidedly naff.

Fondue sets are available again as everything 70s is fun once more. For real authenticity, source the genuine article from the 70s on eBay. Look for bright orange fondue pots and forks with teak handles.

Soda syphon

The retro style soda syphon (or soda siphon), once a symbol of kitsch and bad taste, is now the height of retro cool. The Sparklets Soda Syphon was a hit at 70s parties. However, its roots go back to the era of the Boer War.

The Sparklets Soda Syphon was originally used as a way of bringing sparkling or aerated water to hot climates at the far reaches of the British Empire. Invented in the 1890s, Sparklets bulbs were used during the Boer War.

Before the introduction of Sparklets bulbs, carbonated, or aerated water, as the Victorians preferred to call it, was a luxury product. It was expensive to make, and there was no way to do it yourself. The invention of the Sparklets bulb popularised it as soda water. The original device was called a ‘Prana’ Sparklet Syphon, and the Company stressed that it was as easy for a housemaid in Bayswater as for an orderly in South Africa to use the device.

Sparklets Streamline, with hammered finish 1940s

In 1920 Sparklets Ltd was acquired by BOC, the British Oxygen Company. By the 1960s Sparklets specialised in diecast products for the domestic industry. Naturally the Sparklets Soda Syphons were a big part of the business, but Sparklets also made diecast parts for washing machines, hairdryers and vacuum cleaners, as well as for cars.

The Sparklets bulb method may not have changed much since the days of the Boer War, but the style of the syphon moved with the times. Three basic types were around in the 60s and 70s.

Cigarettes

Player’s No6 and Embassy. However, they were joined by mild versions: Embassy Extra Mild and Player’s No6 Extra Mild. The rise of the mild cigarette was a 70s’ phenomenon. Benson and Hedges Silk Cut, pictured bottom middle, started this trend.

Which? Magazine named Silk Cut as the mildest UK cigarette in 1972. Although, the Which report was intended to convince people to stop smoking, it gave an enormous boost to Silk Cut sales. (In fact there is no evidence to suggest mild cigarettes are any better for you.).

The other big trend ran in the opposite direction. King size cigarettes were increasingly popular. John Player Special, with its distinctive black packaging, was a rival for Benson and Hedges.

King size cigarettes also went down market and were available in the cheaper brands. Both Player’s No6 and Embassy had king size versions. You could buy cigarettes in a bewildering number of different sizes: international, king size, regular, intermediate, mini and sub-mini. Collectors of cigarette packets from the 70s should look out for different sizes in all the popular brands, for example, Silk Cut, Silk Cut King Size, Silk Cut No1, Silk Cut No5, Silk Cut No3, as well as Silk Cut Extra Mild.

At the same time competition from US cigarette manufacturers started in earnest in the 70s. The famous Marlboro brand with is cowboy print advertising campaign started to take sales away from the home grown brands.

Smoking in the 1970s

Cigarettes were a big part of life in the 70s. People smoked them in large numbers. They also started to kick the habit in large numbers too. To give up or not, and to inhale or not, were big topics of conversation.

In 1969, Embassy Filter (right) was the most popular brand. It had been introduced in 1962 and took a staggering 24% of the cigarette market in 1968. By 1971 though, it was knocked off the top spot by Players No 6. In 1972 these brands (below) made up 94% of all cigarettes sold (in order of tar content, lowest first):

Silk Cut (filter)

Consulate Menthol (filter)

Cadets (filter)

Piccadilly De Luxe (filter)

Cambridge (filter)

Embassy Gold (filter)

Embassy Regal (filter)

Sovereign (filter)

Sterling (filter)

Player’s No 6 Virginia (filter)

Park Drive (filter)

Kensitas (filter)

Embassy (filter)

Gold Leaf Virginia (filter)

Player No 6 (plain)

Player’s Weights (plain)

Albany (filter)

Woodbine (plain)

Player’s No 10 Virginia (filter)

Guards Tipped (filter)

Benson & Hedges King Size (filter)

Senior Service (plain)

Player’s Navy Cut (plain)

Park Drive (plain)

Rothman’s King Size (filter)

The majority of the most popular brands are filter tipped. At the time people wanted to believe that the filter would protect them. Medical research showed otherwise, even as early as the 60s. Also worth noting is that Rothman’s advertised their cigarettes as for "…when you know what doing are doing" – a bit ironic considering the tar content!

In 1970, 55% of men and 44% of women smoked cigarettes. The percentage smoking cigarettes had fallen from the peak of 65% in 1948 and the risks of smoking on health were beginning to slowly sink in. In spite of research by the late Professor Sir Richard Doll published in 1951, which linked smoking with lung cancer, cigarette smoking was so much a part of life that the habit died hard. Even as late as 1973 the Guinness Book of Records described nicotine as an "anodyne to civilisation".

In 1971, cigarette manufacturers agreed to put a mild health warning on the packets (left) – "WARNING by HM Government SMOKING CAN DAMAGE YOUR HEALTH". I say "mild" because Professor Sir Richard Doll’s research showed that of 1,357 men with lung cancer, 99.5% were smokers. Or as "Which" chillingly put it – you had as much chance of dying before you were 44 if you smoked, as a serviceman had of being killed in the Second World War. Most people were still playing Russian Roulette and hoping that the chamber was empty.

"Which" never published a report comparing one cigarette brand with another. They acted in the best interest of consumers and recommended only that people should give up. There were conflicting stories circulating concerning the safety of other forms of smoking, such as pipe or cigar smoking: "Was it safer than cigarettes?", "Was it safe if you didn’t inhale?" and "Was it worth waiting for a safe cigarette?". "Which" did not sit on the fence and told members as directly as possible that the only safe course of action was to give up.

The 70s was the decade when people did finally accept the risks of smoking and the proportion of the population who smoked fell quite significantly. Those leading the way were the professional middle classes. The anti-smoking group, ASH, was founded in 1970 and took a lead in alerting the public to the dangers of smoking. The proportion of men and women smoking cigarettes dropped gradually during the 70s. By 1980, 42% of men and 37% of women smoked. (Today’s figures are 27% and 25% respectively).

LED watch

LED digital watch

Retro style LED watches are now selling on the internet, reviving the original digital watches from the early 70s. The first LED watch was marketed in the US by watchmaker, Hamilton, under the brand name ‘Pulsar’ in the Fall of 1971. It was originally a high priced gadget; by the end of the decade LED watches were almost throw away items and the more familiar LCD display was gaining ground.

Toys

The Space Hopper, the Raleigh Chopper and Mattel’s model cars with Hot Wheels made their debut in the 60s, but in the 70s achieved their highest popularity.

The Chopper was revised with safety improvements to become the Mark 2 in 1972. Mattel did not have their own way for long with Hot Wheels. British rival Matchbox had already introduced Superfast Wheels in 1969 and converted their whole range to them in the early 70s.

Sindy continued to be a popular toy for girls and won Toy of the Year in 1970. That accolade also went to another doll in 1971, Katie KopyKat; Katie copied everything you wrote.

Another 70s’ craze that had its origins in the 60s was Klackers, or Clackers: two acrylic balls that were made to click together. Experts could make them clack at the bottom and top in a circular movement, but safety concerns saw their early demise.

The Mastermind TV programme hosted by Magnús Magnússon had huge audiences in the 70s. However, the Mastermind Board Game made by Invicta in 1973 had no connection with the Mastermind TV show. It was all about breaking a secret code.

Lego was as popular as ever. It scooped Toy of the Year in 1974 and 1975. Other toys with their origins in the 50s and earlier were discovered by new generations of children.

The football game Subbuteo gained plastic figures in 1967 and in the 70s was available in up to fifty different team strips. There were spin-off cricket and snooker games too.

Scalextric was improved with new cars in the 70s and was as popular as ever. More traditional toys such as Hornby trains and Meccano continued to find a market.

The big change in play in the 70s though was the advent of electronic games. The 70s gave us digital watches and pocket calculators and by the middle of the decade electronic toys and games as well. One of the first to capture the imagination of the UK public was Adman Grandstand, which could play a variety of sports, including a version of the Pong arcade game. The brightly coloured MB Simon game was also a big seller in 1978.

Star Wars was in the cinema in 1977 and a host of Star Wars inspired merchandise followed. Never before had the movie makers cashed in so much on the toy market, it was a portent for the new decade.

Furniture

Furniture from the seventies was bigger and chunkier than furniture from the 60s. Teak was still the favourite wood throughout the decade, although pine was getting an increasingly strong middle class following. Autumn colours were in vogue: browns, beiges and oatmeal. Striped upholstery fabric was popular.

The seventies had its share of fads. Chrome plated tubular steel furniture had a brief period of being the latest thing. Towards the end of the decade, cane and rattan furniture started to gain a small following. Both this and pine were much bigger in the following two decades.

The seventies was still a decade when modern was the favourite look. There was little attempt to recreate the past, although in a decade of contradictions, reproduction furniture had a growing niche following.

Green Shield Stamps

Green Shield Stamps were almost everywhere in the Britain of the 60s and 70s. If you bought your groceries at certain shops the retailer gave you stamps to stick in a book. Once you had collected enough you exchanged the books for gifts. Most people can remember Green Shield Stamps, but there were other schemes. Does anyone remember Blue Star, Gift Coupon, Happy Clubs, Thrift Stamp, Uneedus Bonus, Universal Sales Promotions or Yellow Stamps?

Drink

In the later 70s, lager began to take hold. You can still get seventies favourites such as Skol, Carling Black Label (they paid a consultant millions of pounds to recommend that the ‘Black Label’ was dropped some time in the 90s), Carlsberg and Tennant’s Pilsner, though whether it is the same, who could say? Light ale was a popular alternative to lager at the time.

Keg bitter was definitely the drink of the early seventies. "Classics" such as Watneys Red Barrel (or Watney’s Red as they tended to call it then), Double Diamond, Courage Tavern and Worthington ‘E’ are well out of production.

Britain’s best selling cars from the 70s

British automotive fashions changed. As women replaced mini skirts with midis and maxis, and men chucked out the Don Draper look in favour of flares and wide ties, cars changed just as significantly, on the outside at least.

Car makers ditched the chrome grills, the wood and leather interiors of the 60s and embraced American coke bottle styling, plastic fascias and matt black grills.

The UK’s top four manufacturers all introduced new models leading up to and around 1970. The first of the new wave was the Ford Escort, launched in late 1967. It was a small car with neat American influenced body styling. Ford also launched the ground breaking Capri in 1969, which brought sports car styling to the average motorist. In 1970 there was a rash of new models: the Morris Marina; a completely restyled Vauxhall Viva; and the all new Hillman Avenger, remember those L shaped tail lights? In 1971 Ford launched the car that was to represent the 1970s, the Cortina Mk III.

Ford won the sales war and the Cortina was the best selling car of the decade, with the Escort in second place. BL made a series of mistakes, the worst of which was to replace their best selling Austin/Morris 1100/1300 range with the blob shaped Allegro. It eventually needed the State to intervene and save the company from bankruptcy.

The 70s also saw a greater proportion of foreign cars on the road. However, none of them made it into the top ten. The best selling foreign import was the Datsun Sunny, which was only the 19th best selling car of the decade.

These are the top ten best selling UK cars of the 70s.

Ford Cortina Mk3, 1972

Ford’s stylists had their fingers firmly on the pulse of the 70s’ car market. They replaced the neatly minimalist Cortina Mk II, driven by Michael Caine in Get Carter, with the glamorous Mk III in 1970.

If there was a car that summed up the mood of the early 70s perfectly it was the Cortina Mk III. The classic American inspired coke bottle styling was combined with plenty of chrome trim. The new Cortina was bigger and better than the outgoing Mk II.

Ford’s graduated model range offered a huge choice of trim, style and engine size. You could choose from from L (basic), XL (more luxury), GT (sporty), GXL (luxurious) to the ultimate Cortina, the 2000E. Even the L looked stylish, but the upmarket GXL offered acres of simulated wood trim, glorious velour seats and a chrome trimmed black vinyl roof.

Ford Cortina Mk V, 1979

In 1976 Ford replaced the Cortina Mk III with the Mk IV. The glam rock era had faded by 1976 and Ford stylists gave the market something more sober, although the parent company’s policy of sharing as much as possible between the UK Cortina and the German Ford Taunus may have also influenced the more prosaic styling.

The final facelift for the Cortina came in 1979. Ford sharpened up the style of the Mk IV with the similar looking Mk V, which nevertheless changed almost every body panel. The Cortina disappeared entirely in 1982 to make way for the Sierra, dubbed the ‘jelly mould’ car at the time.

Ford Escord Mk2, 1979

Ford also sold over one million Escorts in the 1970s. The Escort was introduced late in 1967 as a replacement for the popular Ford Anglia. Remember that backward sloping rear roofline?

The Escort continued the Anglia theme of a stylish body combined with basic, but reliable, mechanicals. However, Ford went one stage further with the Escort, as with the Cortina, they offered a range of basic saloons and some sporty and luxury models as well.

Style was all important to Ford’s selling strategy and in 1975 they gave the Escort a new squared off body and models near the top of the range had square headlamps too. By 1979 you could choose from 1100, 1300, 1600, 1800 and 2000cc models. In 1980 the Escort was upgraded to a the Mk III for the new decade.

Mini Clubman

Although Alex Issigonis’ masterpiece the Mini was eleven years old by 1970, it was still one of Britain’s best selling cars. BL chose to drop the Austin and Morris labels and the car was now just called the ‘Mini’.

In the1970s there was a basic range comprising a Mini 850 and a Mini 1000, with 850cc and 1000cc engines. BL offered a more upmarket version, the Clubman, with a squared off nose. There was an estate version with fake wood panels on the outside and a sports 1275 GT version.

Laurence Moss, the estate agent husband of man-eating Beverly in "Abigail’s Party" drove a Mini, getting a new one every year. He claimed the design did alter, in reality BL made very few changes to the design throughout the 70s. By the end of the decade part of the charm of the car was that it had not changed.

The Mini continued in production for another two decades before being replaced by the new Mini in 2000.

Morris Marina TC, 1972

BL’s executives originally planned the Marina as a replacement for the aging Morris Minor and a serious competitor for the Escort. Learning the lessons of the past they wanted to give it plenty of style and hired ex-Ford stylist, Roy Haynes.

Haynes wanted the two door version to appeal to the under thirty age group. He wanted the interior styling to be exotic and wild.

Somehow BL ended up producing a much bigger car than intended, even though it shared some of its mechanical heritage with the venerable Morris Minor. In reality the Marina sold considerably less well than expected. It achieved a creditable fourth position in sales in the 70s, but was not capable of rescuing BL from its financial troubles. Read more about the Morris Marina.

Vauxhall Firenza, 1971

Vauxhall was like Ford, a British car maker with an American parent – General Motors. Like Ford they followed the same approach: a basic rugged car with an up to the minute body. The Viva had been around since 1963 and had already had one facelift. In 1970 Vauxhall revised it again.

The new Viva, called the HC, was still a small car and in the Escort class, nevertheless it looked wide, low and stylish. Like Ford, Vauxhall offered a range of engines and options. At the top of the range was the sporty Firenza SL.

The Viva really was a car for the 70s. It starred in 1999 in the 1970s’ revival comedy, ‘The Grimleys’ as Shane Titley’s car. Vauxhall dropped it in 1979.

Austin 1300GT, 1971

The Austin/Morris 1100/1300 range was a top selling car in the 1960s. BL found it hard to find a replacement for it. So hard in fact that they failed to do so until 1973. So because of its continued strong sales in the first years of the 70s, the 1100/1300 finds itself at number six.

For the 70s there were some detail improvements and some great 70s’ colours including purple and bright orange. Just like its cousins from the 60s, the 1100s and 1300s were spacious, reliable and mechanically simple.

If you fancied something a little sportier, there was the Austin 1300GT which was a tuned up version of the basic car with a black vinyl roof. BL replaced this best seller with the Allegro in 1973.

Austin Allegro

Where Ford got 70s’ style right with the Cortina, BL got it wrong with the Allegro.

Launched in 1973, the Allegro was styled by internal stylist, Harris Mann. It certainly looked 70s. However, where the Cortina emphasised size and width, the Allegro was rounded and dumpy. There was a bizarre selection of different style front grilles complemented with rounded rectangular headlamps matched inside the car with a rounded square steering wheel, called a Quartic.

Vanden Plas 1500 (Allegro)

A range of engines sizes from 1100 to 1750cc, a rather stylish small estate and a posh Vanden Plas version with real wood facia, leather seats and picnic tables failed to impress buyers. Surprisingly BL failed to provide a hatchback version even though the Allegro shape suited it, and they had been making the hatchback Maxi since 1969.

The Allegro was not a great hit with the public. Whilst the 1100/1300 range was chalking up annual sales of 100,000+ units every year, the Allegro failed to achieve more than 65,000. This styling misjudgment certainly contributed to BL’s collapse in 1975.

There was an unfortunate side effect to the 70s’ style lettering on the boot: to some ‘Austin Allegro’ looked like ‘Rustin Allegro’. The Austin All-aggro was another name for it.

When Austin-Rover dropped the Allegro range in 1982 to make room for the Maestro there were few sad faces.

Ford Capri 2000GT, 1972

Ford advertised the Capri as the car you have always promised yourself. The Capri offered the motoring public something entirely new. It was almost a sports car, with a comfortable four-seater saloon cabin, gorgeous fastback styling and a price tag that the man in the street could afford.

Launched in 1969, the Capri sold well throughout the 70s. Like the Cortina, Ford offered a huge range of engines and trim levels. Like the Cortina, there were several styling revisions, but the basic look and personality remained the same.

At the top of the Capri range was the 3000E, which offered outstanding performance with a top speed of 122mph and 0-60mph in eight seconds. The brochure cooed about such refinements as reclining seats, an electric clock and push button radio. The prestige motoring experience was completed by a a steering wheel and gear knob covered in simulated leather.

Hillman Avenger 1300DL, 1975

Rootes Group (Hillman, Singer, Sunbeam, Humber) launched the Hillman Avenger in 1970. It was a completely new car. The Avenger was mechanically unexciting, but offered a stylish new body with black grill with coke bottle styling and a sloping rear end.

The black grill was made from plastic. The Avenger also had some very distinctive L shaped rear a lamp clusters.

The Avenger was smaller than Rootes Group’s Hillman Hunter and competed with the Escort and Viva. It sold steadily throughout the 1970s. There was a facelift in 1976 and it later became the Chrysler Avenger as the American parent began to assert itself more strongly.

Austin Maxi, 1972

The Austin Maxi could have been a world beater. It was one of the first hatch back cars, and it was one of the first mass-market cars to have a five-speed gear box. Partly designed by Alec Issigonis, it was spacious and handled well. However, the Maxi never lived up to expectations.

The original design, launched in 1969, was very plain looking and not liked by the public. The gearbox was awful and the 1500cc engine was not powerful enough for the car.

The Maxi had a major facelift in 1971. There was a new grill, a more attractive wood finish fascia and a new 1750cc engine. In this form it enjoyed modest sales throughout most of the 70s. People loved the practicality of the hatchback and with the seats folded down it was big enough to transport a double mattress and perfectly capable of carrying garden waste to the tip or a tent or two on holiday.

1970s major household expenses

1. Transport

The average household weekly spend on transport in 2007 was £62. That includes everything from bus tickets to buying cars and petrol. In 1971, that £62 would have been just £6. That would barely cover a tube ticket today.

2. Recreation and culture

In 2007, we spent an average of £57 per week on things like holidays, cinema trips, sports activities and gambling. At 1971 prices, that would cost around £6 again – probably about the price of a large bucket of popcorn today.

3. Housing, fuel and power

£52 per week in 2007, £5 per week in 1971. Obviously that includes expenses like mortgage payments, rent and energy bills. Oh how times have changed.

4. Food and drink

In 2007, we spent £54 per week (I must admit I find that hard to believe, looking at my own till receipts, but still). Thirty-eight years ago that would have cost a mere fiver. Oh and over two thirds of the money we spend on food goes to the big supermarkets – so much for the nation of shopkeepers.

5. Restaurants and hotels

Weekly cost in 2007? £37. In 1971 that would have cost about £4, but then I doubt we would have used them as much in those days anyway.

6. Clothing and footwear

Despite our collective obsession with labels and fashion, we only spent £22 per week on clothes in 2007. Imagine how svelte we would all look if that still only set us back £2. Then again, we’d probably have to be clad head to toe in denim, so maybe £22 is a price worth paying.

7. Communication

Presumably this means telephones, mobiles, broadband and the like. Well, we spent an average of £12 a week on this kind of thing in 2007, which is equivalent to £1 in 1971 (OK, OK so we didn’t have mobiles and broadband back then, but that’s not really the point)

8. Everything else

This includes things like education and health, insurance and whatever else we spend our money on. Anyway, in 2007, these miscellaneous items cost a whopping £128 per week. In 1971, you’d have got the lot for £13. So in 2007, the total average household spend per week was a little under £460. Ouch. If we were to enter some kind of weird price time-warp that would come down to a total of about £46 per week.

Meanwhile, the latest research shows that the average household income in 2006 was about £650. Given the perilous state of our savings, you have to wonder where the extra £210 per week went (We only spent £460 of it remember).

Whichever way you look at it though, that time warp is looking rather appealing. We’ve already got the strikes and the recession, so to earn £650 a week and spend only £46 of it would make it all worthwhile.

It’s never going to happen of course, but it’s a nice dream.

1970s: Fewer cars but more smokers

*In 1971, UK residents made 6.7 million holiday trips abroad.

*In 1970/71, there were 621,000 students in the UK in higher education.

*In 1974, 26 per cent of men and 13 per cent of women in Great Britain who smoked regularly were classed as heavy smokers.

*In 1970, life expectancy at birth for males in the UK was 68.7 years and for females was 75.0 years.

*In 1970, there were 340,000 first marriages in England and Wales.

*In 1970, nearly half (48 per cent) of all households in Great Britain did not have regular use of a car.

*In 1971, the average household size in Great Britain was 2.9 people per household, with one-person households accounting for 18 per cent of all households.

*In 1971, the proportion of babies born to women aged under 25 in England and Wales was 47 per cent (369,600 live births).

*In 1970, food and non-alcoholic drinks was the largest category of expenditure, accounting for 21 per cent of UK total domestic household expenditure.

Life expectancy is perhaps the most notable single change. In 1970, when Edward Heath had just become Prime Minister and The Beatles were breaking up, for men it was 68.7 years and for women it was 75 years; 40 years on, these figures have shifted substantially. Male life expectancy is now 77.8 years, and for women it is 81.9 years. Doubtless the fall in heavy smoking has played a part in that. In 1974, 24 per cent of men and 13 per cent of women in Britain who smoked regularly were classed as heavy smokers, whereas in 2008 the figures were 7 per cent of men and only one in 20 women.

1971 vs 2011: what you get for your money

Mars bar: 1971: 2p 2011: 60p

First class stamp: 1971: 3p 2011: 44p

Pint of milk: 1971: 6p 2011: 49p

Loaf of bread: 1971: 9½p 2011: £1.10

Pint of bitter: 1971: 11p 2011: £3.05

Bunch of bananas: 1971: 18p 2011: 65p

Packet of cigarettes: 1971: 27p 2011: £7

Gallon of petrol: 1971: 33p 2011: £6

Ticket to Wembley Cup Final: 1971: £2 2011: £115

Automotive Load

Image by A.Myers

This load went from a stamping plant in Findlay, OH to a raw material manufacturer in Sheboygan, WI for recycling. It’s a very hard plastic material that is heat-molded and cut for the base interior lining of vehicles.

Some cool auto moulds china images:

Steven F. Udvar-Hazy Center: P-38 Lightning, with B-29 Enola Gay behind it

Image by Chris Devers

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Lockheed P-38J-10-LO Lightning

In the P-38 Lockheed engineer Clarence "Kelly" Johnson and his team of designers created one of the most successful twin-engine fighters ever flown by any nation. From 1942 to 1945, U. S. Army Air Forces pilots flew P-38s over Europe, the Mediterranean, and the Pacific, and from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Lightning pilots in the Pacific theater downed more Japanese aircraft than pilots flying any other Allied warplane.

Maj. Richard I. Bong, America’s leading fighter ace, flew this P-38J-10-LO on April 16, 1945, at Wright Field, Ohio, to evaluate an experimental method of interconnecting the movement of the throttle and propeller control levers. However, his right engine exploded in flight before he could conduct the experiment.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Company

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 390 x 1170cm, 6345kg, 1580cm (12ft 9 9/16in. x 38ft 4 5/8in., 13988.2lb., 51ft 10 1/16in.)

Materials:

All-metal

Physical Description:

Twin-tail boom and twin-engine fighter; tricycle landing gear.

Long Description:

From 1942 to 1945, the thunder of P-38 Lightnings was heard around the world. U. S. Army pilots flew the P-38 over Europe, the Mediterranean, and the Pacific; from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Measured by success in combat, Lockheed engineer Clarence "Kelly" Johnson and a team of designers created the most successful twin-engine fighter ever flown by any nation. In the Pacific Theater, Lightning pilots downed more Japanese aircraft than pilots flying any other Army Air Forces warplane.

Johnson and his team conceived this twin-engine, single-pilot fighter airplane in 1936 and the Army Air Corps authorized the firm to build it in June 1937. Lockheed finished constructing the prototype XP-38 and delivered it to the Air Corps on New Year’s Day, 1939. Air Corps test pilot and P-38 project officer, Lt. Benjamin S. Kelsey, first flew the aircraft on January 27. Losing this prototype in a crash at Mitchel Field, New York, with Kelsey at the controls, did not deter the Air Corps from ordering 13 YP-38s for service testing on April 27. Kelsey survived the crash and remained an important part of the Lightning program. Before the airplane could be declared ready for combat, Lockheed had to block the effects of high-speed aerodynamic compressibility and tail buffeting, and solve other problems discovered during the service tests.

The most vexing difficulty was the loss of control in a dive caused by aerodynamic compressibility. During late spring 1941, Air Corps Major Signa A. Gilke encountered serious trouble while diving his Lightning at high-speed from an altitude of 9,120 m (30,000 ft). When he reached an indicated airspeed of about 515 kph (320 mph), the airplane’s tail began to shake violently and the nose dropped until the dive was almost vertical. Signa recovered and landed safely and the tail buffet problem was soon resolved after Lockheed installed new fillets to improve airflow where the cockpit gondola joined the wing center section. Seventeen months passed before engineers began to determine what caused the Lightning’s nose to drop. They tested a scale model P-38 in the Ames Laboratory wind tunnel operated by the NACA (National Advisory Committee for Aeronautics) and found that shock waves formed when airflow over the wing leading edges reached transonic speeds. The nose drop and loss of control was never fully remedied but Lockheed installed dive recovery flaps under each wing in 1944. These devices slowed the P-38 enough to allow the pilot to maintain control when diving at high-speed.

Just as the development of the North American P-51 Mustang, Republic P-47 Thunderbolt, and the Vought F4U Corsair (see NASM collection for these aircraft) pushed the limits of aircraft performance into unexplored territory, so too did P-38 development. The type of aircraft envisioned by the Lockheed design team and Air Corps strategists in 1937 did not appear until June 1944. This protracted shakedown period mirrors the tribulations suffered by Vought in sorting out the many technical problems that kept F4U Corsairs off U. S. Navy carrier decks until the end of 1944.

Lockheed’s efforts to trouble-shoot various problems with the design also delayed high-rate, mass production. When Japan attacked Pearl Harbor, the company had delivered only 69 Lightnings to the Army. Production steadily increased and at its peak in 1944, 22 sub-contractors built various Lightning components and shipped them to Burbank, California, for final assembly. Consolidated-Vultee (Convair) subcontracted to build the wing center section and the firm later became prime manufacturer for 2,000 P-38Ls but that company’s Nashville plant completed only 113 examples of this Lightning model before war’s end. Lockheed and Convair finished 10,038 P-38 aircraft including 500 photo-reconnaissance models. They built more L models, 3,923, than any other version.

To ease control and improve stability, particularly at low speeds, Lockheed equipped all Lightnings, except a batch ordered by Britain, with propellers that counter-rotated. The propeller to the pilot’s left turned counter-clockwise and the propeller to his right turned clockwise, so that one propeller countered the torque and airflow effects generated by the other. The airplane also performed well at high speeds and the definitive P-38L model could make better than 676 kph (420 mph) between 7,600 and 9,120 m (25,000 and 30,000 ft). The design was versatile enough to carry various combinations of bombs, air-to-ground rockets, and external fuel tanks. The multi-engine configuration reduced the Lightning loss-rate to anti-aircraft gunfire during ground attack missions. Single-engine airplanes equipped with power plants cooled by pressurized liquid, such as the North American P-51 Mustang (see NASM collection), were particularly vulnerable. Even a small nick in one coolant line could cause the engine to seize in a matter of minutes.

The first P-38s to reach the Pacific combat theater arrived on April 4, 1942, when a version of the Lightning that carried reconnaissance cameras (designated the F-4), joined the 8th Photographic Squadron based in Australia. This unit launched the first P-38 combat missions over New Guinea and New Britain during April. By May 29, the first 25 P-38s had arrived in Anchorage, Alaska. On August 9, pilots of the 343rd Fighter Group, Eleventh Air Force, flying the P-38E, shot down a pair of Japanese flying boats.

Back in the United States, Army Air Forces leaders tried to control a rumor that Lightnings killed their own pilots. On August 10, 1942, Col. Arthur I. Ennis, Chief of U. S. Army Air Forces Public Relations in Washington, told a fellow officer "… Here’s what the 4th Fighter [training] Command is up against… common rumor out there that the whole West Coast was filled with headless bodies of men who jumped out of P-38s and had their heads cut off by the propellers." Novice Lightning pilots unfamiliar with the correct bailout procedures actually had more to fear from the twin-boom tail, if an emergency dictated taking to the parachute but properly executed, Lightning bailouts were as safe as parachuting from any other high-performance fighter of the day. Misinformation and wild speculation about many new aircraft was rampant during the early War period.

Along with U. S. Navy Grumman F4F Wildcats (see NASM collection) and Curtiss P-40 Warhawks (see NASM collection), Lightnings were the first American fighter airplanes capable of consistently defeating Japanese fighter aircraft. On November 18, men of the 339th Fighter Squadron became the first Lightning pilots to attack Japanese fighters. Flying from Henderson Field on Guadalcanal, they claimed three during a mission to escort Boeing B-17 Flying Fortress bombers (see NASM collection).

On April 18, 1943, fourteen P-38 pilots from the 70th and the 339th Fighter Squadrons, 347th Fighter Group, accomplished one of the most important Lightning missions of the war. American ULTRA cryptanalysts had decoded Japanese messages that revealed the timetable for a visit to the front by the commander of the Imperial Japanese Navy, Admiral Isoroku Yamamoto. This charismatic leader had crafted the plan to attack Pearl Harbor and Allied strategists believed his loss would severely cripple Japanese morale. The P-38 pilots flew 700 km (435 miles) at heights from 3-15 m (10-50 feet) above the ocean to avoid detection. Over the coast of Bougainville, they intercepted a formation of two Mitsubishi G4M BETTY bombers (see NASM collection) carrying the Admiral and his staff, and six Mitsubishi A6M Zero fighters (see NASM collection) providing escort. The Lightning pilots downed both bombers but lost Lt. Ray Hine to a Zero.

In Europe, the first Americans to down a Luftwaffe aircraft were Lt. Elza E. Shahan flying a 27th Fighter Squadron P-38E, and Lt. J. K. Shaffer flying a Curtiss P-40 (see NASM collection) in the 33rd Fighter Squadron. The two flyers shared the destruction of a Focke-Wulf Fw 200C-3 Condor maritime strike aircraft over Iceland on August 14, 1942. Later that month, the 1st fighter group accepted Lightnings and began combat operations from bases in England but this unit soon moved to fight in North Africa. More than a year passed before the P-38 reappeared over Western Europe. While the Lightning was absent, U. S. Army Air Forces strategists had relearned a painful lesson: unescorted bombers cannot operate successfully in the face of determined opposition from enemy fighters. When P-38s returned to England, the primary mission had become long-range bomber escort at ranges of about 805 kms (500 miles) and at altitudes above 6,080 m (20,000 ft).

On October 15, 1943, P-38H pilots in the 55th Fighter Group flew their first combat mission over Europe at a time when the need for long-range escorts was acute. Just the day before, German fighter pilots had destroyed 60 of 291 Eighth Air Force B-17 Flying Fortresses (see NASM collection) during a mission to bomb five ball-bearing plants at Schweinfurt, Germany. No air force could sustain a loss-rate of nearly 20 percent for more than a few missions but these targets lay well beyond the range of available escort fighters (Republic P-47 Thunderbolt, see NASM collection). American war planners hoped the long-range capabilities of the P-38 Lightning could halt this deadly trend, but the very high and very cold environment peculiar to the European air war caused severe power plant and cockpit heating difficulties for the Lightning pilots. The long-range escort problem was not completely solved until the North American P-51 Mustang (see NASM collection) began to arrive in large numbers early in 1944.

Poor cockpit heating in the H and J model Lightnings made flying and fighting at altitudes that frequently approached 12,320 m (40,000 ft) nearly impossible. This was a fundamental design flaw that Kelly Johnson and his team never anticipated when they designed the airplane six years earlier. In his seminal work on the Allison V-1710 engine, Daniel Whitney analyzed in detail other factors that made the P-38 a disappointing airplane in combat over Western Europe.

• Many new and inexperienced pilots arrived in England during December 1943, along with the new J model P-38 Lightning.

• J model rated at 1,600 horsepower vs. 1,425 for earlier H model Lightnings. This power setting required better maintenance between flights. It appears this work was not done in many cases.

• During stateside training, Lightning pilots were taught to fly at high rpm settings and low engine manifold pressure during cruise flight. This was very hard on the engines, and not in keeping with technical directives issued by Allison and Lockheed.

• The quality of fuel in England may have been poor, TEL (tetraethyl lead) fuel additive appeared to condense inside engine induction manifolds, causing detonation (destructive explosion of fuel mixture rather than controlled burning).

• Improved turbo supercharger intercoolers appeared on the J model P-38. These devices greatly reduced manifold temperatures but this encouraged TEL condensation in manifolds during cruise flight and increased spark plug fouling.

Using water injection to minimize detonation might have reduced these engine problems. Both the Republic P-47 Thunderbolt and the North American P-51 Mustang (see NASM collection) were fitted with water injection systems but not the P-38. Lightning pilots continued to fly, despite these handicaps.

During November 1942, two all-Lightning fighter groups, the 1st and the 14th, began operating in North Africa. In the Mediterranean Theater, P-38 pilots flew more sorties than Allied pilots flying any other type of fighter. They claimed 608 enemy a/c destroyed in the air, 123 probably destroyed and 343 damaged, against the loss of 131 Lightnings.

In the war against Japan, the P-38 truly excelled. Combat rarely occurred above 6,080 m (20,000 ft) and the engine and cockpit comfort problems common in Europe never plagued pilots in the Pacific Theater. The Lightning’s excellent range was used to full advantage above the vast expanses of water. In early 1945, Lightning pilots of the 12th Fighter Squadron, 18th Fighter Group, flew a mission that lasted 10 ½ hours and covered more than 3,220 km (2,000 miles). In August, P-38 pilots established the world’s long-distance record for a World War II combat fighter when they flew from the Philippines to the Netherlands East Indies, a distance of 3,703 km (2,300 miles). During early 1944, Lightning pilots in the 475th Fighter Group began the ‘race of aces.’ By March, Lieutenant Colonel Thomas J. Lynch had scored 21 victories before he fell to antiaircraft gunfire while strafing enemy ships. Major Thomas B. McGuire downed 38 Japanese aircraft before he was killed when his P-38 crashed at low altitude in early January 1945. Major Richard I. Bong became America’s highest scoring fighter ace (40 victories) but died in the crash of a Lockheed P-80 (see NASM collection) on August 6, 1945.

Museum records show that Lockheed assigned the construction number 422-2273 to the National Air and Space Museum’s P-38. The Army Air Forces accepted this Lightning as a P-38J-l0-LO on November 6, 1943, and the service identified the airplane with the serial number 42-67762. Recent investigations conducted by a team of specialists at the Paul E. Garber Facility, and Herb Brownstein, a volunteer in the Aeronautics Division at the National Air and Space Museum, have revealed many hitherto unknown aspects to the history of this aircraft.

Brownstein examined NASM files and documents at the National Archives. He discovered that a few days after the Army Air Forces (AAF) accepted this airplane, the Engineering Division at Wright Field in Dayton, Ohio, granted Lockheed permission to convert this P-38 into a two-seat trainer. The firm added a seat behind the pilot to accommodate an instructor who would train civilian pilots in instrument flying techniques. Once trained, these test pilots evaluated new Lightnings fresh off the assembly line.

In a teletype sent by the Engineering Division on March 2, 1944, Brownstein also discovered that this P-38 was released to Colonel Benjamin S. Kelsey from March 3 to April 10, 1944, to conduct special tests. This action was confirmed the following day in a cable from the War Department. This same pilot, then a Lieutenant, flew the XP-38 across the United States in 1939 and survived the crash that destroyed this Lightning at Mitchel Field, New York. In early 1944, Kelsey was assigned to the Eighth Air Force in England and he apparently traveled to the Lockheed factory at Burbank to pick up the P-38. Further information about these tests and Kelsey’s involvement remain an intriguing question.