Check out these plastic automobile instrument panel china images:

pictures

Nice China Automotive Plastic Injection Parts Makers pictures

A few good china automotive plastic injection parts producers photos I identified:

Cool Auto Exterior Mould Maker pictures

A couple of nice auto exterior mould maker photos I discovered:

Bazile (30)

Image by Douglas R Witt

Now that Bazile is back in one piece, it’s time to do a tiny added operate in the back of the mask. The pictures in this collection have taken spot over the last three day… this is a time of waiting and working sections… it requires time for the mask to settle and dry, this operate demands to be accomplished somewhat gradually if you are to get a mask that isn’t warped out of shape. There are a couple of items that I do to hold it from deforming.

I use the original armature in this case it is a plaster life cast of my teacher/actor friend Sean Daly. I place the mask back over the plaster armature to make certain it will not warp out of face shape.

I have discovered that Papier-mâching the inside of a mask should be completed in stages… begin with the middle attributes like the eyes nose and mouth… than Papier-mâché outward. Leave the rim of the mask as the final factor to mâché … this can be rapidly or slow… based how massive the mask is and how considerably interior work wants to be done… Bazile mask is nevertheless drying 72 hours later. It’s just starting to harden…

The purpose it’s taken this long is due to the fact of two factors. It is been raining a lot right here and it is created the apartment far more humid than standard, the other and the primary purpose is due to the fact I employed a TP Paste (the white stuff) to fill some of the huge damaging spaces like the nose, around the eyes, ears and bottom lip. The white stuff that you are searching at is a mixture of all-objective white glue and shredded bathroom tissue.

I use this TP Paste to fill in a few areas of the mask that I really feel require some protection from put on and tear just in case it gets bumped whilst becoming utilized on stage. After I have utilised the TP Paste to fill in the places of the mask I want to straighten I will leave it to dry for six hours or more.

Warning: this mixture need to be employed sparingly due to the fact it takes a lengthy whilst to dry, also if you use a ton of it will make the mask heavier difficult to wear.

Even although I didn’t use really considerably of this Paste it will take three days plus to completely dry. I don’t use it quite often, but it is truly a great thing to us to fill gaps. It’s like a mask maker’s auto body filler to smooth some uneven exterior lumps and it strengthens the mask, I felt this mask want it and what a excellent likelihood to show you 🙂 super mask generating secretes

I do one more six layers of Papier-mâché in the back of the masks. This will bulk up the mask a bit and give it some added stability for frequent use on stage or using as a teaching mask. In these photographs the 1st point I did was use the TP fill and then let it sit to settle and dry in front of a fan for 16 hours. Then I cut out the ear holes, nostrils and trimmed the rim of the mask. After I am happy with the timing I Papier-mâché six layers on the interior of the mask starting with the middle functions in the mask and worked my way outward. I did the eye, ears, nose, chin and cheek area. Then I let it settles in front of the fan for one more 8 hours. When it was dry I completed the brows and forehead and Papier-mâché the rim of the mas with smaller sized ribbons of paper, this will seal the mask completely and hold it from possibly chipping for flaking apart from you’re face sweat and warm breath from typical use… it also makes it appear nice.

After all six layers of mâché are finish… put in front of the fan once again and let it sit and dry again for at least eight hours… there has been a lot of new operate completed on the mask and you will notice that it will be heavier… there is due to a lot of water added to the mask and it requirements to dry out and settle… put it on the armature base you sculpted the mask on and leave it sit for a day or overnight.

Now that the mask is dry… it is time to add the fabric elastic head band, you can us any sort of head band suits your fancy or what ever turns you on… String, Ribbon, leather, Fabric elastic, etc… the way to attach them is basically the very same although my strategy is not the only way… and you are welcome to explore other people.

For Bazile mask I am making use of a half inch black fabric elastic, you can choose it up at any location that sells fabric. I use black simply because it disappears on stage and it never appears dirty. I start off by measuring a length of fabric elastic from temple to temple. Coming around the crown of the back of the head and sitting behind the ears like a pair of sunglasses. I pull the elastic just a tiny snug (NOT TIGHT) you want the mask to match a snuggly on your face… in the next set of photographs I will be showing how to add foam rubber to the interior of the mask so it will sit comfortable on the face.

After I have measured out my length of elastic set it aside and get a marker, place the mask on your face and find your temples on the inside of the mask. When you have marked exactly where the elastic is going to go, use a tiny dab of hot glue and glue the elastic in… and attempt the mask on. This might take a handful of tries so use a little hot glue till you locate a comfortable fit. The mask may sit on your face a bit uncomfortable… it might be pressing into the corners of your eyes of sitting quite snuggly to your face… that’s ok because that’s what the foam rubber is for.

The discomfort will show you exactly where to place the foam… ha ha ha!

When the mask fits snuggly it is time to use a small more hot glue to anchor the fabric elastic into the mask, attempt to make the glue as flat as attainable utilizing the tip of the hot gun so that you’re not obtaining poked in the temples by hot glue lumps. Then Papier-mâché three more layers of paper more than and about the fabric elastic and set the mask in front of a fan to dry for another six hours or so… it’s crucial to give the mask lots of drying time. The next methods are the sealing and painting and you want a good dry mask to function on.

Particular person artist note to newbie mask makers:

The back of the mask is just as critical as the front of the mask. Most folks believe it ends with taking the mask off the mold. But if you commit a couple of further hours detailing and finishing the back of the mask you are going to have a mask that will final longer and take a beating or hang on a wall with out deforming over time.

It is important to also reinforce the back and fill in some of the damaging spaces… and add ventilation holes like nostrils and often a small mouth slit. This will aid the actor from overheating and reduce down on sweating behind the mask. Some masks will fit really close to the face and subsequently create a vacuum effect that is like placing a plastic bag more than your face. The capacity to breath very easily out of the mask is crucial it will aid the actor overlook there wearing a mask, also if all you have are eyeholes as venation entrance and exit the flow of air will dry out the performer’s eyes.

Please listen to this music although viewing this set of pictures

youtu.be/9HtHEgINHO0

Good Plastic Auto Moulding Production pictures

A handful of nice plastic auto moulding production pictures I discovered:

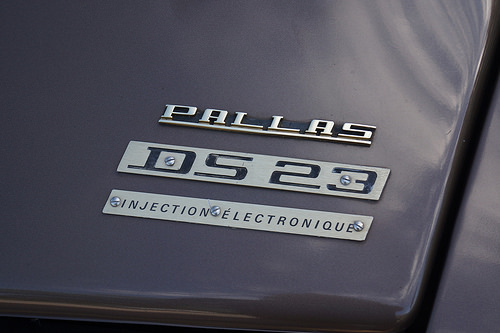

1973 Citroen DS23 Pallas

Image by DVS1mn

CITROEN DS23 PALLAS

When in 1955 Citroen released its DS19 ‘Goddess’, media commentators reviewed the vehicle in tones previously reserved for objects arriving from the depths of outer space.

Hydro-pneumatic suspension, assistance systems for the steering, brakes and gearshift lever, and inboard front disc brakes were among the advances pioneered by this extraordinary design.

By 1968 the rest of the globe had begun adopting aspects of Citroen’s radical package nonetheless, Citroen wasn’t finished exploring the variety of quirks it could pack into a medium-sized sedan. One particular new function to perplex the home mechanic was a hyperlink that would swivel headlights in unison with the front wheels.

The car’s capability to traverse rough terrain was proved in 1969 when a Citroen was set to win the first London-Sydney Marathon, only to be taken out in a critical collision with a spectator vehicle. Five years later, the Australian crew of a DS23 got the job done, dominating a 1974 World Cup Rally that sent competitors from South America to Munich by way of the Sahara Desert.

Sustaining a DS is perform for specialist technicians or probably the seriously talented amateur. There is barely area below the bonnet of a Pallas to see engine components, let alone put a spanner on them.

Three-speed automatics were plagued by troubles and stay challenging to keep, so get a 5-speed manual if you can. Overseas values are supplying a large hint that anybody who wants a actually great Pallas demands to act quickly. Be prepared to invest the better element of ,000. Of numerous thousand automobiles sold new in Britain, fewer than 300 are known to survive and numbers in Australia will be far slimmer.

TRAPS AND Ideas

Packing a mass of electro/mechanical/hydraulic bits plus the total drivetrain into a tiny space ahead of the firewall didn’t assist Citroen’s reputation for reliability.

Maintaining your Citroen cool is crucial to engine longevity and that can be costly. A single spare components web site was quoting genuine but renovated radiators at a lot more than 00. Replacing the coolant hoses with a set of genuine items will cost a lot more than .

Citroen club internet sites of late have carried requests for help in locating a competent trimmer for DS models. This suggests that discovering someone to repair a car with worn seats and compromised head-lining has turn into challenging.

FROM THE WHEELS ARCHIVES

Words: Paul Blank – January, 2005

The DS was spectacularly bold, wrote Paul Blank…

When the time came to replace the Traction Avant, the resulting auto could be expected to be absolutely remarkable – and it was.

The new auto, launched at the Paris Salon in 1955, was referred to as DS, which, when pronounced in French, is "Day-ess", which translates to Goddess. At the Paris Salon an amazing quantity of orders have been taken for the new vehicle – some 12,000 people signing on the dotted line.

In 1955 Australians had been purchasing new FJ Holdens and the Morris Minor was considered a modern day little vehicle in England. The DS may as well have been a spaceship in comparison. It certainly looked like

absolutely nothing else.

The automobile floated along at any speed. Famously, the DS featured Hydropneumatic suspension. It had the cars sitting on suspension units which have been steel spheres in location of classic springs and shock absorbers. The ride in a DS has to be knowledgeable to be believed. Even if a tyre blew, the car would compensate.

One more DS feature was the use of disc brakes. It was Citroen which very first fitted them to a mass-production vehicle.

Inside, the DS was as spectacularly bold as the rest of the auto. In an era of flat tin or wood dashboards, Citroen used the largest single piece of moulded plastic in the world. The DS in not a complex automobile just quite various.

You know the car’s prepared when very first the back, then the front of the automobile lift up to standard ride height. To modify gear, you lift off, switch to the next gear and accelerate away again. Then you have to discover about the brakes. Exactly where you may count on a brake pedal, there’s a black rubber mushroom. It operates like a valve operating by the "the tougher you push, the far more you stop" method, with virtually no pedal travel offered.

The DS isn’t a sports car it is a genuine Grand Tourer and, treated as such, offers a magical expertise.

SPECIFICATIONS

Citroen DS23 Pallas

Quantity constructed: 582,593 (All ID/DS 1968-75)

Body: All-steel, integrated physique/chassis four-door sedan and station wagon

Engine: 2347cc inline four-cylinder, OHV, 8v, fuel injection

Power & torque: 105kW @ 5500rpm, 200Nm @ 4000rpm

Performance: -97km/h 10.2sec -400m 17.3sec

Transmission: 3-speed automatic, 5-speed manual

Suspension: Independent with wishbones, pneumatic struts and anti-roll bar (f) Independent with trailing arms, pneumatic struts and anti-roll bar (r)

Brakes: Discs, power-assisted

Tyres: 185HR15 radial

Value range: 00-,000

Contact: Citroen Clubs in a variety of states,

www.ds23.co.nz/

Click right here for more automobile pictures at my Flickr web site.

1973 Citroen DS23 Pallas

Image by DVS1mn

CITROEN DS23 PALLAS

When in 1955 Citroen released its DS19 ‘Goddess’, media commentators reviewed the vehicle in tones previously reserved for objects arriving from the depths of outer space.

Hydro-pneumatic suspension, help systems for the steering, brakes and gearshift lever, and inboard front disc brakes were amongst the advances pioneered by this extraordinary design and style.

By 1968 the rest of the planet had begun adopting elements of Citroen’s radical package nevertheless, Citroen wasn’t completed exploring the range of quirks it could pack into a medium-sized sedan. One new feature to perplex the residence mechanic was a link that would swivel headlights in unison with the front wheels.

The car’s potential to traverse rough terrain was proved in 1969 when a Citroen was set to win the very first London-Sydney Marathon, only to be taken out in a significant collision with a spectator car. Five years later, the Australian crew of a DS23 got the job done, dominating a 1974 Planet Cup Rally that sent competitors from South America to Munich by way of the Sahara Desert.

Maintaining a DS is perform for specialist technicians or maybe the seriously talented amateur. There is barely area beneath the bonnet of a Pallas to see engine elements, let alone place a spanner on them.

3-speed automatics were plagued by issues and remain difficult to preserve, so get a 5-speed manual if you can. Overseas values are offering a huge hint that any individual who wants a really excellent Pallas needs to act quickly. Be prepared to invest the far better part of ,000. Of many thousand automobiles sold new in Britain, fewer than 300 are identified to survive and numbers in Australia will be far slimmer.

TRAPS AND Suggestions

Packing a mass of electro/mechanical/hydraulic bits plus the complete drivetrain into a small space ahead of the firewall didn’t aid Citroen’s reputation for reliability.

Keeping your Citroen cool is vital to engine longevity and that can be pricey. A single spare components website was quoting authentic but renovated radiators at a lot more than 00. Replacing the coolant hoses with a set of genuine products will cost a lot more than .

Citroen club web sites of late have carried requests for assist in locating a competent trimmer for DS models. This suggests that finding a person to repair a car with worn seats and compromised head-lining has turn into challenging.

FROM THE WHEELS ARCHIVES

Words: Paul Blank – January, 2005

The DS was spectacularly bold, wrote Paul Blank…

When the time came to replace the Traction Avant, the resulting automobile could be expected to be absolutely remarkable – and it was.

The new auto, launched at the Paris Salon in 1955, was named DS, which, when pronounced in French, is "Day-ess", which translates to Goddess. At the Paris Salon an wonderful number of orders have been taken for the new automobile – some 12,000 men and women signing on the dotted line.

In 1955 Australians have been purchasing new FJ Holdens and the Morris Minor was regarded a modern day small auto in England. The DS may as well have been a spaceship in comparison. It certainly looked like

nothing else.

The auto floated along at any speed. Famously, the DS featured Hydropneumatic suspension. It had the vehicles sitting on suspension units which were steel spheres in spot of standard springs and shock absorbers. The ride in a DS has to be knowledgeable to be believed. Even if a tyre blew, the auto would compensate.

Yet another DS feature was the use of disc brakes. It was Citroen which initial fitted them to a mass-production automobile.

Inside, the DS was as spectacularly bold as the rest of the car. In an era of flat tin or wood dashboards, Citroen used the greatest single piece of moulded plastic in the planet. The DS in not a complicated auto just really diverse.

You know the car’s ready when 1st the back, then the front of the car lift up to typical ride height. To change gear, you lift off, switch to the subsequent gear and accelerate away once again. Then you have to understand about the brakes. Exactly where you may count on a brake pedal, there’s a black rubber mushroom. It works like a valve operating by the "the tougher you push, the much more you stop" program, with virtually no pedal travel accessible.

The DS is not a sports automobile it is a actual Grand Tourer and, treated as such, gives a magical knowledge.

SPECIFICATIONS

Citroen DS23 Pallas

Number built: 582,593 (All ID/DS 1968-75)

Physique: All-steel, integrated body/chassis four-door sedan and station wagon

Engine: 2347cc inline 4-cylinder, OHV, 8v, fuel injection

Power & torque: 105kW @ 5500rpm, 200Nm @ 4000rpm

Functionality: -97km/h 10.2sec -400m 17.3sec

Transmission: 3-speed automatic, 5-speed manual

Suspension: Independent with wishbones, pneumatic struts and anti-roll bar (f) Independent with trailing arms, pneumatic struts and anti-roll bar (r)

Brakes: Discs, energy-assisted

Tyres: 185HR15 radial

Value range: 00-,000

Contact: Citroen Clubs in different states,

www.ds23.co.nz/

Click right here for far more auto photos at my Flickr site.

Cool Auto Molds Made In China pictures

Verify out these auto molds made in china pictures:

Steven F. Udvar-Hazy Center: View of south hangar, such as B-29 Superfortress “Enola Gay”, a glimpse of the Air France Concorde, and a lot of other folks

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the 1st bomber to residence its crew in pressurized compartments. Though made to fight in the European theater, the B-29 discovered its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-constructed B-29-45-MO dropped the first atomic weapon utilized in combat on Hiroshima, Japan. 3 days later, Bockscar (on display at the U.S. Air Force Museum close to Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance climate reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

General: 900 x 3020cm, 32580kg, 4300cm (29ft 6 five/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished all round aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish all round, normal late-Globe War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin 509th Composite Group markings painted in black "Enola Gay" in black, block letters on lower left nose.

Cool China Box Mold pictures

Some cool china box mold pictures:

Steven F. Udvar-Hazy Center: Grumman F6F-3 Hellcat

Image by Chris Devers

Quoting Smithsonian National Air and Space Museum | Grumman F6F-three Hellcat:

The Grumman F6F Hellcat was originally conceived as an advanced version of the U.S. Navy’s then current front-line fighter, the F4F Wildcat (see NASM collection). The Wildcat’s intended replacement, the Vought F4U Corsair (see NASM collection), initial flown in 1940, was displaying great guarantee, but improvement was slowed by issues, including the crash of the prototype.

The National Air and Space Museum’s F6F-3 Hellcat, BuNo. 41834, was constructed at Grumman’s Bethpage, New York, factory in February 1944 beneath contract NOA-(S)846. It was delivered to the Navy on February 7, and arrived in San Diego, California, on the 18th. It was assigned to Fighter Squadron 15 (VF-15) on USS Hornet (CV12) bound for Hawaii. On arrival, it was assigned to VF-three where it sustained harm in a wheels-up landing at NAS Barbers Point, Hawaii. Right after repair, it was assigned to VF-83 exactly where it was employed in a coaching function till February 21, 1945. Soon after quite a few transfers 41834 was converted to an F6F-3K target drone with the installation of sophisticated radio-control equipment. It was painted red with a pink tail that carried the number 14. Its mission was to be utilised in Operation Crossroads – the atomic bomb tests at Bikini Atoll. It flew on June 24, 1946, with a pilot, on a practice flight and was launched, unmanned, quickly soon after the 1st bomb test. Instrumentation on board and photographic plates taped to the handle stick obtained data on radioactivity. 3 much more manned flights preceded the final unmanned flight on July 25, 1946, which evaluated the first underwater explosion. Records indicate that exposure of this aircraft to the radioactive cloud was minimal and residual radiation is negligible.

F6F-3K 41834 was transferred to NAS Norfolk and logged its final flight on March 25, 1947, with a total of 430.2 flying hours. It was assigned to the National Air Museum on November 3, 1948, and remained at Norfolk until October four, 1960, when it was moved by barge to Washington and placed in storage. In 1976 this Hellcat was loaned to the USS Yorktown Museum at Charleston, South Carolina. A superficial restoration was performed at the museum, but due to the fact of the harsh environment and its poor condition the Hellcat was returned to NASM on March 16, 1982. In 1983, it was sent to Grumman Aerospace exactly where a team of volunteers fully restored the aircraft. In 1985, it was shipped back to the Paul E. Garber Preservation, Restoration and Storage Facility in Suitland, Maryland, and put in storage. NASM’s F6F-3 Hellcat is scheduled to be displayed in the new Steven F. Udvar-Hazy center at Dulles International Airport in Virginia in 2004.

Transferred from the United States Navy.

Manufacturer:

Grumman Aircraft Engineering Corporation

Date:

1943

Nation of Origin:

United States of America

Dimensions:

General: 338 x 1021cm, 4092kg, 1304cm (11ft 1 1/16in. x 33ft 5 15/16in., 9021.2lb., 42ft 9 three/8in.)

Physical Description:

Heavy armor plate, reinforced empennage, R-2800-10W engine, spring tabs on the ailerons (increased maneuverability), could carry rockets as effectively as bombs.

Image from page 21 of “Examples of Chinese ornament chosen from objects in the South Kensington museum and other collections” (1867)

Image by Internet Archive Book Pictures

Identifier: examplesofchines00jone

Title: Examples of Chinese ornament selected from objects in the South Kensington museum and other collections

Year: 1867 (1860s)

Authors: Jones, Owen

Subjects:

Publisher: London : S. & T. Gilbert, 4 Copthall Buildings, E.C. Back of the Bank of England

Contributing Library: Philadelphia Museum of Art, Library

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Pictures From Book

Click right here to view book on the web to see this illustration in context in a browseable on-line version of this book.

Text Appearing Just before Image:

ottle. There is muchof the Indian character in this instance, particularlyin the detached flowers at the base of the topic. Plate XCIV. From a painted china Jar. Composition on thefragmentary principle remarkable for the boldtreatment of the prime and bottom of the jar. Plate XCV. From a painted china Vase. Yet another compo-sition on the fragmentary principle. Plate XCVI. From a painted china Bottle. A singular com-position remarkable for the way in which the effectof the sturdy colour of the ornament is softened bythe judicious treatment of the ground. Plate XCVII. From a painted china Bottle. Composition onthe continuous-stem principle. The ornament inthis instance is in slight relief. The vase was castin a mould. Plate XCVIII. Inlaid bronze Dish. Composition on Plate XCIX. From a painted china Bottle,the continuous-stem principle. Plate C. From a painted china Vase. This example canhardly be named ornament: it is conventionalonly in the way in which the leaves and fruit arebalanced.

Text Appearing Soon after Image:

Ornament from an Indian Lacquer Box. 15 u.

Note About Images

Please note that these pictures are extracted from scanned web page photos that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original operate.

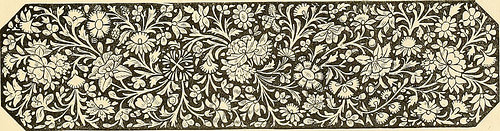

Image from page 520 of “The industries of Japan : with each other with an account of its agriculture, forestry, arts, and commerce. From travels and researches undertaken at the cost of the Prussian government” (1889)

Image by World wide web Archive Book Images

Identifier: industriesofjapa00rein

Title: The industries of Japan : collectively with an account of its agriculture, forestry, arts, and commerce. From travels and researches undertaken at the cost of the Prussian government

Year: 1889 (1880s)

Authors: Rein, J. J. (Johannes Justus), 1835-1918 Rein, J. J. (Johannes Justus), 1835-1918. Japan nach Reisen und Studien. V. 2. Land- und Forstwirthschaft, Industrie und Handel. English Hodder and Stoughton, publisher

Subjects: Industries Agriculture Art, Japanese

Publisher: London : Hodder and Stoughton

Contributing Library: Getty Research Institute

Digitizing Sponsor: Getty Research Institute

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book online to see this illustration in context in a browseable on the web version of this book.

Text Appearing Prior to Image:

ut in water withpaddles, and then left to rest for a quick time that the coarser andheavier particles may possibly settle to the bottom. The separation of thefine floating paste is effected by opening 1 or the other of thetap-holes, of which there are usually 4 placed irregularly oneabove the other. Finally, the complete pulpy mass is passed througha fine cloth sieve, which separates all the coarse grains and otherimpurities. Funnel-shaped boxes are employed in location of our filter presses.The walls are produced of staves. On the bottom is a layer of gravel1 Ein Ausfiug ins Armenische, Kolti. Zeitung, 21/two, 1886. CERAMICS. 465 or perfectly fine washed material with a straw mat laid more than it.When the pasty substance is poured in, the water filters partlythrough, although the clay paste is deposited steadily. The waterwhich collects upon it is drained off via a side opening, andthe material is dried in a red-hot furnace and ultimately worked upand kneaded with the feet and hands. When this is carried out, it is

Text Appearing Right after Image:

Fig. 19.—TEAPOT OF GREY-BROWN STONE-WARE : FROM KUWANA, IN ISE. left to ferment in a pit or damp chest, not for a year, as wasformerly the case in China, it is mentioned, but for a few weeks ormonths, before employing in the factory. By far the largest element of the clay-wares of Japan are shaped onthe Rokuro or potters wheel. The apparatus employed for this II. H H 466 ART Business AND Associated OCCUPATIONS. purpose is mostly of the simplest kind, the shaping board servingat the exact same time as the swinging-wheel. It has a hole near theedge in which a rod, 20 centimeters lengthy, is placed, by which it isset in motion. In a a lot more created state, as at Arita, for instance,the bigger wheel is bound firmly to the shaping board, some 20 to30 centimeters apart, by four rods, and is turned with the feet.Plaster of Paris moulds and castings of the material are as un-frequent as the employment of patterns and models. These areindeed striking wants, but the Japanese substitutes for them hisgreat skill in the ha

Note About Pictures

Please note that these images are extracted from scanned web page pictures that could have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not completely resemble the original perform.

Nice China Automobile Molds Factory pictures

Check out these china automobile molds factory images:

Stalinorgel. Stalin’s Organ. Сталинский орган.

Image by Peer.Gynt

Katyusha multiple rocket launchers (Russian: Катюша) are a variety of rocket artillery first built and fielded by the Soviet Union in Planet War II. Compared to other artillery, these numerous rocket launchers deliver a devastating quantity of explosives to an location target speedily, but with decrease accuracy and requiring a longer time to reload. They are fragile compared to artillery guns, but low-cost and easy to produce. Katyushas of World War II, the initial self-propelled artillery mass-made by the Soviet Union,[1] have been usually mounted on trucks. This mobility gave Katyushas (and other self-propelled artillery) one more benefit: getting capable to provide a big blow all at once, and then move prior to being positioned and attacked with counter-battery fire.

Katyusha weapons of Globe War II included the BM-13 launcher, light BM-8, and heavy BM-31. These days, the nickname is also applied to newer truck-mounted Soviet numerous rocket launchers—notably the typical BM-21—and derivatives.

The nickname

Initially, the secrecy kept their military designation from becoming recognized by the soldiers who operated them. They had been known as by code names such as Kostikov Guns (soon after the head of the RNII), and lastly classed as Guards Mortars.[two] The name BM-13 was only permitted into secret documents in 1942, and remained classified until right after the war.[three]

Due to the fact they have been marked with the letter K, for Voronezh Komintern Factory,[3] Red Army troops adopted a nickname from Mikhail Isakovsky’s well-known wartime song, Katyusha, about a girl longing for her absent beloved, who is away performing military service.[4] Katyusha is the Russian equivalent of Katie, an endearing diminutive form of the name Katherine: Yekaterina →Katya →Katyusha.

German troops coined the sobriquet Stalin’s organ (German: Stalinorgel), soon after Soviet leader Joseph Stalin for its visual resemblance to a church musical organ and alluding to the sound of the weapon’s rockets. They are known by the identical name in Sweden. [four]

The heavy BM-31 launcher was also referred to as Andryusha (Андрюша, “Andrew”, endearing diminutive).[five]

Katyushas of Planet War II

Katyusha rocket launchers have been mounted on several platforms throughout Planet War II, which includes on trucks, artillery tractors, tanks, and armoured trains, as properly as on naval and riverine vessels as assault support weapons.

The style was relatively simple, consisting of racks of parallel rails on which rockets were mounted, with a folding frame to raise the rails to launch position. Every truck had amongst 14 and 48 launchers. The 132-mm diameter M-13 rocket of the BM-13 program was 180 centimetres (70.9 in) long, 13.2 centimetres (five.two in) in diameter and weighed 42 kilograms (92 lb). Initially, the caliber was 130 mm, but the caliber was changed (initial the designation, and then the actual size), to avoid confusing them with normal artillery shells[3]. It was propelled by a solid nitrocellulose-primarily based propellant of tubular shape, arranged in a steel-case rocket engine with a single central nozzle at the bottom finish. The rocket was stabilised by cruciform fins of pressed sheet steel. The warhead, either fragmentation, high-explosive or shaped-charge, weighed around 22 kg (48 lb). The range of the rockets was about five.four kilometres (3.4 mi). Later, 82-mm diameter M-8 and 310-mm diameter M-31 rockets were also developed.

The weapon is much less accurate than standard artillery guns, but is really successful in saturation bombardment, and was particularly feared by German soldiers. A battery of 4 BM-13 launchers could fire a salvo in 7–10 seconds that delivered four.35 tons of high explosives over a 4-hectare (ten acres) effect zone.[two] With an efficient crew, the launchers could redeploy to a new place immediately following firing, denying the enemy the opportunity for counterbattery fire. Katyusha batteries were often massed in quite huge numbers to generate a shock impact on enemy forces. The weapon’s disadvantage was the lengthy time it took to reload a launcher, in contrast to conventional guns which could sustain a continuous low price of fire.

The sound of the rocket launching also was distinctive in that the continuous "woosh" sound that came from the firing of the rockets could be employed for psychological warfare. The rocket’s devastating destruction also helped to decrease the morale of the German army.

Development

Katyushas of Planet War II

Katyusha rocket launchers were mounted on numerous platforms in the course of World War II, including on trucks, artillery tractors, tanks, and armoured trains, as nicely as on naval and riverine vessels as assault support weapons.

The design and style was relatively easy, consisting of racks of parallel rails on which rockets were mounted, with a folding frame to raise the rails to launch position. Each truck had in between 14 and 48 launchers. The 132-mm diameter M-13 rocket of the BM-13 method was 180 centimetres (70.9 in) extended, 13.2 centimetres (five.2 in) in diameter and weighed 42 kilograms (92 lb). Initially, the caliber was 130 mm, but the caliber was changed (initial the designation, and then the actual size), to keep away from confusing them with typical artillery shells[three]. It was propelled by a solid nitrocellulose-based propellant of tubular shape, arranged in a steel-case rocket engine with a single central nozzle at the bottom end. The rocket was stabilised by cruciform fins of pressed sheet steel. The warhead, either fragmentation, higher-explosive or shaped-charge, weighed about 22 kg (48 lb). The range of the rockets was about five.four kilometres (three.4 mi). Later, 82-mm diameter M-8 and 310-mm diameter M-31 rockets were also developed.

The weapon is significantly less correct than conventional artillery guns, but is incredibly successful in saturation bombardment, and was especially feared by German soldiers. A battery of 4 BM-13 launchers could fire a salvo in 7–10 seconds that delivered four.35 tons of high explosives over a four-hectare (10 acres) impact zone.[two] With an efficient crew, the launchers could redeploy to a new location quickly after firing, denying the enemy the chance for counterbattery fire. Katyusha batteries have been usually massed in extremely large numbers to produce a shock impact on enemy forces. The weapon’s disadvantage was the long time it took to reload a launcher, in contrast to standard guns which could sustain a continuous low rate of fire.

The sound of the rocket launching also was unique in that the constant "woosh" sound that came from the firing of the rockets could be utilised for psychological warfare. The rocket’s devastating destruction also helped to reduced the morale of the German army.

Combat history

BM-13 battery fire, throughout the Battle of Berlin, April 1945, with metal blast covers pulled over the windshields

The a number of rocket launchers had been top secret in the starting of World War II. A specific unit of the NKVD secret police was raised to operate them.[2] On July 7, 1941, an experimental artillery battery of seven launchers was 1st used in battle at Orsha in Belarus, below the command of Captain Ivan Flyorov, destroying a station with several provide trains, and causing enormous German Army casualties. Following the achievement, the Red Army organized new Guards Mortar batteries for the help of infantry divisions. A battery’s complement was standardized at 4 launchers. They remained below NKVD handle till German Nebelwerfer rocket launchers became widespread later in the war.[six]

A battery of BM-31 multiple rocket launchers in operation

On August eight, 1941, Stalin ordered the formation of eight Special Guards Mortar regiments under the direct manage of the General Headquarters Reserve (Stavka-VGK). Each and every regiment comprised 3 battalions of three batteries, totalling 36 BM-13 or BM-8 launchers. Independent Guards Mortar battalions were also formed, comprising 36 launchers in 3 batteries of twelve. By the end of 1941, there had been eight regiments, 35 independent battalions, and two independent batteries in service, holding a total of 554 launchers.[11]

In June 1942 Heavy Guards Mortar battalions were formed about the new M-30 static rocket launch frames, consisting of 96 launchers in three batteries. In July, a battalion of BM-13s was added to the establishment of a tank corps.[12] In 1944, the BM-31 was used in Motorized Heavy Guards Mortar battalions of 48 launchers. In 1943, Guards Mortar brigades, and later divisions, have been formed equipped with static launchers.[11]

By the end of 1942, 57 regiments have been in service—together with the smaller independent battalions, this was the equivalent of 216 batteries: 21% BM-8 light launchers, 56% BM-13, and 23% M-30 heavy launchers. By the end of the war, the equivalent of 518 batteries had been in service.[11]

[edit] Katyushas since World War II

Russian forces use BM-27 rocket launchers during the Second Chechen War

The accomplishment and economy of multiple rocket launchers (MRL) have led them to continue to be created. In the course of the Cold War, the Soviet Union fielded a number of models of Katyushas, notably the BM-21 launchers fitting the stereotypical Katyusha mould, and the larger BM-27. Advances in artillery munitions have been applied to some Katyusha-type a number of launch rocket systems, like bomblet submunitions, remotely-deployed land mines, and chemical warheads.

With the breakup of the Soviet Union, Russia inherited most of its military arsenal such as the Katyusha rockets. In recent history, they have been used by Russian forces in the course of the 1st and Second Chechen Wars and by Armenian and Azerbaijani forces during the Nagorno-Karabakh War. Georgian government forces are reported to have utilised BM-21 or related rocket artillery in fighting in the 2008 South Ossetia war.[13]

Katyushas were exported to Afghanistan, Angola, Czechoslovakia, Egypt, East Germany, Hungary, Iran, Iraq, North Korea, Poland, Syria, and Vietnam. They were also constructed in Czechoslovakia[14], People’s Republic of China, North Korea, and Iran.[citation necessary]

Katyushas also saw action in the Korean War, utilised by the Chinese People’s Volunteer Army against the South and United Nations forces. Soviet BM-13s had been identified to have been imported to China prior to the Sino-Soviet split and had been operational in the People’s Liberation Army.

Israel captured BM-24 MRLs for the duration of the Six-Day War (1967), used them in two battalions in the course of the Yom Kippur War (1973) and the 1982 Lebanon War, and later created the MAR-240 launcher for the identical rockets, primarily based on a Sherman tank chassis. For the duration of the 2006 Lebanon War, Hezbollah fired between 3,970 and 4,228 rockets, from light truck-mounts and single-rail man-portable launchers. About 95% of these have been 122 mm (four.eight in) Syrian-manufactured Katyusha artillery rockets, which carried warheads up to 30 kg (66 lb) and had a range of up to 30 km (19 mi).[15][16].[15][17][18] Hamas has launched 122-mm “Grad-type Katyusha” rockets from the Gaza Strip against a number of cities in Israel,[19] even though they are not reported to have truck-mounted launchers.

Katyushas have been also allegedly utilized by the Rwandan Patriotic Front in the course of its 1990 invasion of Rwanda, by means of the 1994 genocide. They were successful in battle, but translated into much anti-Tutsi sentiment in the neighborhood media.[20]

It was reported that BM-21 launchers had been employed against American forces for the duration of 2003 invasion of Iraq. They have also been utilized in the Afghanistan and Iraq insurgencies. In Iraq, according to Related Press and Agence France-Presse reports, Katyusha rockets had been fired at the Green Zone late March 2008.[21][22]

Cool Automotive Interior Mold Factory pictures

Verify out these automotive interior mold factory images:

Lotus Europa

Image by pedrosimoes7

Cascais Classic Motorshow, Cascais, Portugal

From Wikipedia, the free encyclopedia

OVERVIEW

ManufacturerLotus Cars

Production1966–1975

Numbers produced:

Series S1: 296

Series S1A/S1B: 342

Series S2: four,294

Series Twin Cam: four,950

AssemblyHethel, Norfolk, England

Body and chassis

ClassSports automobile (S)

Body style2-door coupe

LayoutLongitudinal, Rear mid-engine, rear-wheel drive

Powertrain

Engine

1470 cc Renault A1K I4

1565 cc Renault 807 I4

1557 cc Lotus/Ford DOHC I4

DIMENSIONS

Wheelbase91 in (two,311 mm)

Length157.25 in (3,994 mm)

Width64.5 in (1,638 mm)

Height42.5 in (1,080 mm)

Curb weight1,350 to 1,570 lb (610 to 710 kg)

The Lotus Europa name is utilized on two distinct mid-engined GT coupé cars constructed by Lotus Cars. The original Europa and its variants comprise the Lotus Kinds 46, 47, 54, 65 and 74, and had been developed between 1966 and 1975. The second vehicle is the Sort 121 Europa S, a Lotus Elise-derived design made from 2006 to 2010.

EUROPA (1966-1975)

The Europa concept is believed to have originated throughout 1963 with drawings done by Ron Hickman, then director of Lotus Engineering, for Lotus’a bid for the Ford GT40 racing auto project. When that contract was lost to Lola Cars, Chapman chose to use Hickman’s highly effective aerodynamic design, which had a drag coefficient of only Cd .29, as the basis for a new mid-engined production model initially intended to succeed the Lotus 7.

By the mid-1960s, the mid-engine car configuration was nicely-established as the optimal design and style for Grand Prix automobiles, nonetheless almost no road cars yet employed this arrangement. Lotus planned the Europa to be a volume-created, two-seater mid-engined sports coupe constructed to reasonable expense, quite an ambitious purpose for the time.

Like all Lotus automobiles of the era, the Europa was created and constructed following Chapman’s oft-stated philosophy of automotive design: "Simplify, then add lightness". To this end, a number of ingenius design approaches have been made by Lotus to allow it to economically overcome the many challenges presented by the novel mid-engined arrangement.

Production of the original Lotus Europa ceased in 1975, with a total of 9,230 cars of all models obtaining been built.

Style Attributes

Lotus Europa S2 interior (1968 black-badge model).

The Europa employed a lightweight, folded & welded "minimalist" boxed-steel backbone chassis with a fibreglass moulded body, a mixture that was first utilized by Lotus founder Colin Chapman in the Lotus Elan launched in 1962. Earliest versions of the Europa had the physique totally-bonded to the chassis for maximum structural stiffness, nevertheless this was soon changed to a bolted-on physique to let normal chassis and physique repairs to be created.

As opposed to the Elan, the Europa had no front-mounted engine or gearbox to accommodate, and so the Europa’s principal chassis member ran straight forward to intersect a large box-section cross-beam operating across the car amongst the front suspension points. At the rear, the chassis split into a "Y" shape behind the cabin to accommodate the combined engine, transmission and final-drive components, and to support the rear suspension.

ENGINE AND TRANSAXLE

The sourcing of suitable engine, gearbox and final-drive components was regarded critical to the achievement of delivering a low-price mid-engined automobile. Chapman was keen to diversify beyond the Ford elements heavily used in earlier Lotus vehicles, and settled on using the engine and combined transmission/final-drive transaxle units not too long ago released by Renault for their Renault 16.

The 1470cc Renault engine was a light and contemporary design and style (if somewhat pedestrian in the Renault), while the matching Renault 16 transaxle seemed nearly ideal for the Europa project. In the Renault automobile, the transaxle sat ahead of the engine, driving the front wheels. By relocating the combined engine/transaxle unit to the rear of the auto and rotating it 180 degrees in strategy, Lotus could obtain a ready-made contemporary mid-engine configuration – albeit 1 with four reverse gears! By repositioning the differential crownwheel within the final drive assembly, the path of rotation of the output shafts was reversed, as a result correcting this "shortcoming".

The Renault 16’s engine’s design and style was well-suited to Lotus’s needs. It utilized an aluminium block with cast-iron cylinder liners, which saved appreciable weight compared to the cast-iron blocks a lot more widespread at the time. It’s overhead-valve design and style had the camshaft situated higher-up in the block, resulting in a compact valve-train nicely suited for higher-rpm operation. Most importantly, all the engine ancillaries (water pump, belt-drives, alternator) have been driven off a v-belt pulley fixed to the transaxle end of the camshaft instead of getting driven by the engine’s crankshaft. When fitted to the Europa, this pulley location place all the engine’s ancillaries at its rear face giving straightforward access for maintenance, rather than them being positioned tough against the vehicle’s bulkhead as-for most standard engines.

For Lotus use the Renault engine was given a quantity of crucial improvements, like a higher compression ratio (ten.25 alternatively of 8.6), larger inlet valves, revised valve timings, dual valve springs and a twin-barrel carburettor. These alterations lifted the engine’s power by 30% from 63 bhp @ 5000 rpm to 82 bhp @ 6000 rpm.

For US export, a de-tuned 1565cc version was used giving 80 bhp @ 6000 rpm.

Later Europa models have been fitted with the same Ford-based Lotus Twin Cam engine utilized in the Lotus Elan range because 1962. This was a sophisticated, twin-overhead-cam, eight-valve higher-efficiency motor making 105 bhp in original kind (later lifted to 126 bhp in "big-valve" kind), and it was reported that Lotus initially delayed its introduction in the Europa till they had been confident in the strength of the Renault transaxle. The twin-cam engine 1st appeared in the Europa in 1971.

When Renault released their most effective 16 TX model in 1973, it included a strengthened 5-speed transmission. Lotus rapidly offered this gearbox as an selection in the Europa, along with their Massive Valve twin-cam engine.

SUSPENSION

The Europa’s four-wheel independent suspension was also typical Chapman pondering. The front utilised lightweight pressed steel upper and reduced wishbones with a clever coil-more than spring-damper arrangement, all connected to the wheels using off-the-shelf front uprights, ball joints and trunnions. The steering gear was solid-mounted rack and pinion employing Truimph Herald elements.

The rear suspension was a heavily modified version of the Chapman strut, initially developed for Chapman’s earlier Formula racing automobile styles and utilised in the Lotus Elan. In the Europa, the vertical "strut" element pivots on the wheel hub at its reduce end and doesn’t control wheel camber angle as-in earlier Lotus styles. Wheel place and alignment is controlled as an alternative by interaction between a fixed-length, articulated driveshaft top hyperlink, a easy tubular decrease hyperlink, and a massive box-section radius arm operating diagonally forward to the chassis.

These radius arms played a critical part in providing the precise tracking and handling desired, as the Chapman Strut’s use of the driveshaft to resist lateral forces was compromised by the rubber engine and transaxle mounts necessary to isolate vibrations from the auto body. A careful compromise in between the radius arm mount’s stiffness, isolation and automobile handling was needed, culminating ultimately in a sandwich bush that was flexible against shear but stiff in compression and tension.

The car’s subsequent resulting handling prompted automotive writers to describe the Europa as the nearest factor to a Formula car for the road.

Series 1[edit]

Lotus Europa Series 1 (Variety 46)

The Series 1 or S1 Europa (also identified as Lotus Type 46) was announced for sale to European markets on December 20, 1966. The first vehicles were delivered in France in February 1967. Volkswagen owned the rights to the Europa name in Germany, so vehicles for sale in Germany had been badged Europe rather than Europa.

The S1 was fitted with a modified Renault 16 1470 cc inline-4 engine and a four-speed gearbox. The engine was a unique 82 hp (61 kW) version (as opposed to the 52 hp (39 kW) generated in standard type). Lotus adapted the affordable but lightweight Renault engine and gearbox to the revolutionary Europa longitudinal mid-engined layout, inverting the gearbox’s crown wheel on its pinion gear to avoid obtaining 4 reverse gears. The S1 weighed 610 kg (1512 lb). Autocar magazine achieved a prime speed of 121 mph (195 km/h), and did 0–60 mph in 9.3 seconds. Of particular note, in excess of .9 g (eight m/s²) lateral acceleration was regularly accomplished by Car magazine on road tires of that era.

Only 296 examples of the S1 had been manufactured (chassis numbers from 460001 to 460296). These are the rarest on the marketplace. These vehicles had incredibly light and minimalist building, with fixed side windows, fixed seats (adjustable pedals needing the use of tools), no door handles, no internal door covers, and an aluminum dashboard. The steel chassis central beam was sandwiched (incorporated) within the fibreglass bodywork, hence reinforcing stiffness, but producing repair rather complex.

Series 1A and B (about 350 constructed) had removable side windows, wooden dashboard, and internal door panel covers which could accommodate the windows when taken off. Series 1B had a redesigned rear panel, with new, rectangular light clusters.[citation necessary]

Which includes the S1A and S1B (which incorporated some of the later S2 modifications) variations, 644 Europa S1s have been manufactured.

SERIES two

The Europa Series 2, or Lotus Variety 54, was introduced in April 1968 (approximately chassis quantity 0645 onwards). The S2 utilized the very same 1470cc Renault engine and mecahnical components as the earlier Series 1, but added a number of essential refinements including opening electric windows, adjustable seats, a new completely carpeted interior and a polished wooden fascia panel for the dashboard. The most significant alter was the switch from fully-bonded building to the use of bolt fasteners to attach the fibreglass body to the backbone steel frame. Even though decreasing the torsional and flexural stiffneses somewhat, the use of a separable body was welcomed by the automotive insurance business as it greatly reduced the complexity and price of making repairs to the car.

Early examples of the S2 had been externally almost identical to the S1 with the exception of the new windows. From early 1969, secondary front indicator lamp nacelles have been added in between the headlights, and bigger door handles had been utilized in place of the S1’s push-button products. In the course of 1968 a quantity of Europas (and Elans) were made bearing black-and-silver Lotus badges on the nose and steering wheel in place of the customary yellow-and-green ones. The official Lotus Cars website states these "black-badge" automobiles have been to commemorate the tragic death earlier in 1968 of Jim Clark, Lotus’s champion Formula 1 driver, however this is debated by other sources.

1968 Lotus Europa S2. The early S2 models had been developed with S1-style front indicators and door handles. Note the S2 two-pane opening windows.

Modern road tests for the Europa S2 recorded a top speed about 120 mph (195 kph), -60 occasions of 9.3 secs, standing 1/4 mile occasions around 16.7 secs, and an all round fuel economy about 30 mpg (9.4 L/one hundred km).

A modest number of Series 2 cars had been modified to be "federalized" for export to the United States. These Federal Kind 54s had the low front fenders (guards) of the European model and the larger 1565cc engine of the later Lotus Kind 65. These vehicles have been subsequently recalled by Lotus due to the headlamps becoming beneath the regulated US height (a "bug eye" headlamp raiser was later to be installed).

In 1969-70, the Kind 65 (also known as S2 Federal) was born especially for export to the U.S., with extra changes to the body, chassis, suspension and the powerplant to much better comply with U.S. D.O.T. requirements. Amongst the modifications, the engine was a slightly modified emission controlled Renault 16TL 1565 cc engine producing 80 hp rather than the 1470 cc engine of the Kind 54. The front suspension was changed to make the front end of the auto taller along with taller front fenders to raise the headlamps. Road & Track magazine tested the Federal S2 and recorded -60 mph in 9.6 seconds with a prime speed of 116 mph (187 km/h).

In total Lotus produced three,615 Europa S2s.

TWIN CAM AND Unique

In 1971, the Type 74 Europa Twin Cam was produced accessible to the public, with a 105 bhp 1557cc Lotus-Ford Twin Cam engine (105 bhp US "Federal" emission normal emissions handle version with Stromberg carburetors, till the finish of production) and a re-designed bodyshell to increase rearward visibility. Initially with the exact same gearbox as the earlier vehicles, once the supply had been exhausted in 1972 a new stronger Renault four-speed gearbox (Kind 352) was introduced. Mike Kimberley, who rose to turn into chief executive of Group Lotus, then a new engineer at Lotus, was appointed Chief Engineer of the Europa TC project. 1,580 cars had been shipped as Europa "Twin Cam" before Lotus switched to a 126 bhp "Big Valve" version of the engine.

The huge valve "Europa Particular" version was aspirated by Dell’Orto carburettors version of the very same engine in addition it also supplied a new Renault 5-speed (Type 365) gearbox choice. It weighed 740 kg (1631 lb), Motor magazine famously tested a UK Specific to a leading speed of 123 mph (198 km/h), did 0–60 mph in 6.6 seconds, and ran the 1/4 mile in 14.9 sec. This at a time when all road tests were carried out with both a driver and passenger, with only the driver on board the 0–60 mph time would have been well beneath 6 seconds, a phenomenal performance for the period.

1974 LOTUS EUROPA Unique

Introduced in September 1972 the first 100 large valve automobiles have been badged and painted to honour the just won Team Lotus’s 1972 F1 Globe Championship title with John Player Particular as sponsors, all with five-speed gearbox, these had been all black with gold pin stripe matching the livery of the GP cars – plus a numbered JPS dash board badge, becoming the first ever John Player Special commemorative motor autos. The "Special" name and colour scheme was planned to be dropped following the 1st 200 automobiles, reverting to the Twin Cam name, but such was the positive reaction to the new car that the name and pin stripe scheme remained until the end of Europa Production despite the fact that colours other than black have been created accessible.

In the end the numbered plaque distinguished the first, original, 100 JPS cars from other black Europa Specials.

In total 4710 Type 74s have been developed of which 3130 have been badged "Specials".

Sort 47 AND 62

LOTUS Variety 47

Though the original Europa was intended as a clubmans sports racer to replace the Lotus 7, it was realised that the automobile would be uncompetitive with the Renault engines accessible. A choice was for that reason created for Lotus Elements to manufacture a specialist race auto based on the Europa to be raced by Group Lotus and sold to private entrants.

Even though the extremely first Variety 47 was primarily based on a modified Europa, all subsequent automobiles have been produced completely by Lotus Elements rather than the main factory. Launched at the same time as the S1 Europa, the body of the 47 was thinner than the common Europa and with bigger wheel arches. Side vents into the engine bay have been added right after the 1st handful of automobiles experiencing difficulties with engine bay temperature.

The engine, gearbox and rear suspension had been completely different from the normal Europa and have been taken in their entirety from the Lotus 23/Lotus 22 Formula Junior with a Lotus-Ford Twin Cam primarily based 165 hp (123 kW) 1,594 cc Cosworth Mk.XIII dry sump engine, and a Hewland FT 200 five-speed gearbox and suspension with reversed bottom wishbone, top hyperlink and dual radius arms. The front upright was specially cast in common with the F2 version of Lotus 41X to accommodate a larger Girling brake for the later 47A model (which had the Alfa Romeo tail lamp shared with the Europa S2) with reinforced front frame.

The Kind 47 precise production numbers are unknown, the last auto was 47GT-85 but it is unlikely 85 47GT’s had been made, estimates vary from 55 to 68 during the years 1966-70. Although the 47GT is the very best known, a handful of 47F’s were produced, these had the detachable physique equivalent to the S2 Europa, but retaining the massive wheel arches and side vents of the 47GT. Fitted with a tuned Ford cross flow engine but with the Renault gearbox and rear suspension of the Europa. The quantity created is unknown but probably no much more than six.

As a mobile test bed for the new two litre Lotus 907 engine getting developed for the forthcoming Elite and Eclat, the Sort 62 was produced. Only two such cars have been ever created. These have been space frame automobiles with F1 suspension to deal with the 240 hp from the engine. Although deliberately created to resemble the Europa, in practice the only connection to the Europa was a couple of of the Europa’s physique panels. It did win its very first event the 1969 BOAC 500 at Brands Hatch with John Miles and Brian Muir at the wheel. Replica 47’s and 62’s are bespoke-manufactured by Banks Europa Engineering, in a number of variations. A a single-off 47, fitted with a Rover V8 engine (3.five litre enlarged out to four.4 litre), was constructed for GKN in 1968 and registered, GKN 47D, with 300 hp it was capable of 180 mph (290 km/h).

NON-FACTORY CUSTOM SPECIALS

Throughout its life, the Europa attracted the consideration of numerous non-Lotus automotive customising businesses who supplied "special" versions in tiny numbers to the public. Amongst these was the Swiss Lotus importer, who produced two specific versions of the S2 fitted with the Renault 16 TS variety 807 engine, the "Europa Hemi 807" and the fuel injected "Europa Black Shadow 807". The Hemi 807 had 105 PS (77 kW) SAE and could attain 200 km/h (124 mph), even though the Black Shadow had 137 PS (101 kW) on tap. The Black Shadow also received a five-speed gearbox.

These automobiles had a wider track, specific wheels and stickers, white indicator lights up front, and featured extractor vents higher on the side panel behind the rear door. The fuel injection program was from Kugelfischer.

Good Automobile Plastic Components Produced In China pictures

Check out these automobile plastic parts made in china pictures:

Steven F. Udvar-Hazy Center: Photomontage of Overview of the south hangar, such as B-29 “Enola Gay” and Concorde

Image by Chris Devers

Nice Plastic Auto Lamp Mould Maker pictures

Verify out these plastic auto lamp mould maker pictures: