A few nice china car door moulding images I found:

Moulding

Blow Moulding Machine Manufacturer in Ahmedabad | India

Molding

Molding is the procedure of production forming flexible raw content by using a firm frame or model known as a pattern. The maker who creates the pattern is known as Blow Moulding Machine Manufacturer in India. Mold maker use different kinds of device in casting procedure.

Types of Molding Machines

Blow Moulding Machine Manufacturer in Ahmedabad is a production procedure by which empty plastic parts are established. There are main kinds of device use for strike casting. Extrusion strike moulding device assumes top quality components with both air-driven and mechanical systems, and it is suitable for producing PE, PP and PC container items. Blow hypodermic injection casting device are widely used in medicine packaging, the cosmetic packaging, making up chemical market, gifts & toys and so on. Stretch strike casting device three steps in one from raw content to container finish product no more loss in damaged perform. Pet strike casting device is used in bottling procedure of standard water, sodas, delicious oil and farm chemicals.

Mould devices manufacturer creates different kind of device for casting procedure like candle moulding device for create candle lights, pulp moulding device for create egg containers, fruit containers and pallets. In-mold marking device is perfect equipment of many sectors, such as lubricating oil bucket, dressing container, municipal packaging market, etc.

China Molds

China is the largest manufacturer of hypodermic injection pattern devices on the globe and in fact it rated 1st on the globe. In the past several years hypodermic injection pattern device manufacturers have got greatly improved on technological innovation. However compared with those in western Blow Moulding Machine Manufacturer in India suppliers still have a way to catch up on technological innovation and kinds. In detail there is still not little blank on such kinds as super-large or special perfection hypodermic injection pattern machines; meanwhile self-support rate of home-made hypodermic injection pattern devices for items processing, most adopt brought in hypodermic injection pattern devices. Totally research and production of hypodermic injection pattern devices cannot still satisfy demands brought by development of plastic materials market in Chinese suppliers.

http://www.zeelplastmachinery.in/blow-molding-machine.html

World’s Renowned China Plastic Injection Moulding

As the living requirements of the folks all over the planet boost, their item requirements also go up, and the demand for plastic merchandise are going up and therefore China Plastic Injection Moulding plastic moulds specifications have increased. China Plastic Injection Moulding technology has continued to increase every single day. The time taken to make a mould has been shortened due to the availability of effortless communication tools as effectively as info technologies.

Plastic injection moulds are becoming manufactured even though using sophisticated gear, integration technologies as nicely as international management. China Plastic Injection Moulding organizations have been manufacturing moulds considering that time immemorial. These days they have made a lot of improvement to meet the customers’ wants and also market requirements. They do not want to be left behind as technologies takes the manufacturing market forward. Most of China Plastic Injection Moulding firms have set up branch organizations to be in a position to concentrate on diverse plastic moulding products, and for ease of production.

After carrying out solution development for several years, China Plastic Injection Moulding organizations have graduated from basic mould makers to big firms where mass production of plastic moulds is carried out. They have been capable to carry out production plans, and are capable to supply custom plastic moulding solutions to their consumers. For the China Plastic Injection Moulding firms to be where they are these days, they have been focusing a lot on management. They have been able to set up a complete management technique in all their production fields, which includes client care.

China Plastic Injection Moulding firms have become the most searched plastic injection moulding companies all more than the world. They have invested a lot in high-tech processing machines, seasoned engineers and designers, quite strict method handle of projects. Their after-sales help is the very best as compared to other stakeholders in the sector. China Plastic Injection Moulding organizations have also invested heavily on human resource. They have employed experts who are capable to communicate with customers in a number of languages like English, French, Russian, Spanish, Italian, among a lot of other individuals.

A quantity of plastic moulds are manufactured by China Plastic Injection Moulding businesses for diverse markets about the globe. They are in a position to carry out mass production of various sorts of plastic moulds, enabling them to meet the market place demand. Clients are encouraged to make use of China Plastic Injection Moulding companies for all their requirements. You should rest assured that high quality service, coupled with ideal costs shall be supplied to you. Order your plastic moulds today without having worry of high quality or price! You will in no way regret.

Get in touch with Reliable Plastic Injection Moulding Manufacturers for High High quality Molds

To design and style products with intricate style you can opt for plastic injection molding. For the proper mold speak to a trusted plastic injection moulding makers.

Plastic injection molding method is a broadly utilized method which has many advantages more than other sorts of molding. With injection molding, you can attain high rates of production. It is a good thought to use inserts inside the mold when you make a solution. To add strength, you can make use of fillers. In situations of co-injection molding, more than one particular material can be utilised with ease. Upon ejection from the mold, the plastic parts have a higher level of finish. This minimizes the post production function. The scrap can be reused effortlessly resulting in very tiny waste. With injection molding, you can accomplish full automation.

A trustworthy molding procedure

In each day life, a series of plastic items are employed. From combs, mugs, brushes and sunglasses all are plastic items. These merchandise are manufactured by injection molding. Owing to its positive aspects manufacturers adopt this molding process. In comparison to other kinds of molding, this procedure is simple versatile and efficient. It is more dependable than other molding processes. In plastic injection method, molten plastic is shaped into a desired geometry. Raw plastic pellets are put into the mold under high stress.

Understanding injection molding

Soon after the molten plastic is placed in the mold, it is allowed to cool and solidify. After the plastic solidifies, the item is ejected by opening two halves of the mold. With this approach, you can produce plastic parts which have correct dimensions. You can make contact with plastic injection moulding companies if you want to produce toys, automotive parts, furniture and housewares. Themachines with which the injection nodding method is carried out typically operate under high pressure. As the molten plastic presses tough against the mold, the design has greater details.

An array of benefits

For Auto Parts Mould, manufacturers make use of the injection approach. The components can be developed in bulk at low labor fees. When this method is employed much less time is needed to create the various plastic components. A huge number of products can be generated from the very same mold. The plastic injection molding process is totally automated. This molding process is much less complicated than other molding processes. For plastic injection moulding to be successful, the polymer requirements to be injected into the hollow mould with a force.

The procedure in particulars

Clamping the mold is the initial step of the injection molding method. The three regular components are camping unit, injection unit and the mold. A clamp is utilised to hold the mold when the melted plastic is injected. The plastic pellets are placed in the hopper where they are heated till they melt. The molten plastic can be fed into the mold with ease. The mold is clamped and kept beneath pressure till the plastic cools. In the dwelling phase, you have to make confident that all the cavities are filled.

Good Plastic Auto Moulding Production pictures

A handful of nice plastic auto moulding production pictures I discovered:

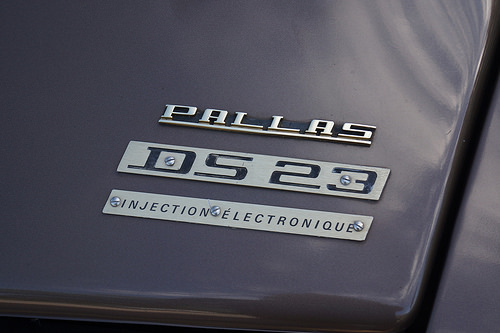

1973 Citroen DS23 Pallas

Image by DVS1mn

CITROEN DS23 PALLAS

When in 1955 Citroen released its DS19 ‘Goddess’, media commentators reviewed the vehicle in tones previously reserved for objects arriving from the depths of outer space.

Hydro-pneumatic suspension, assistance systems for the steering, brakes and gearshift lever, and inboard front disc brakes were among the advances pioneered by this extraordinary design.

By 1968 the rest of the globe had begun adopting aspects of Citroen’s radical package nonetheless, Citroen wasn’t finished exploring the variety of quirks it could pack into a medium-sized sedan. One particular new function to perplex the home mechanic was a hyperlink that would swivel headlights in unison with the front wheels.

The car’s capability to traverse rough terrain was proved in 1969 when a Citroen was set to win the first London-Sydney Marathon, only to be taken out in a critical collision with a spectator vehicle. Five years later, the Australian crew of a DS23 got the job done, dominating a 1974 World Cup Rally that sent competitors from South America to Munich by way of the Sahara Desert.

Sustaining a DS is perform for specialist technicians or probably the seriously talented amateur. There is barely area below the bonnet of a Pallas to see engine components, let alone put a spanner on them.

Three-speed automatics were plagued by troubles and stay challenging to keep, so get a 5-speed manual if you can. Overseas values are supplying a large hint that anybody who wants a actually great Pallas demands to act quickly. Be prepared to invest the better element of ,000. Of numerous thousand automobiles sold new in Britain, fewer than 300 are known to survive and numbers in Australia will be far slimmer.

TRAPS AND Ideas

Packing a mass of electro/mechanical/hydraulic bits plus the total drivetrain into a tiny space ahead of the firewall didn’t assist Citroen’s reputation for reliability.

Maintaining your Citroen cool is crucial to engine longevity and that can be costly. A single spare components web site was quoting genuine but renovated radiators at a lot more than 00. Replacing the coolant hoses with a set of genuine items will cost a lot more than .

Citroen club internet sites of late have carried requests for help in locating a competent trimmer for DS models. This suggests that discovering someone to repair a car with worn seats and compromised head-lining has turn into challenging.

FROM THE WHEELS ARCHIVES

Words: Paul Blank – January, 2005

The DS was spectacularly bold, wrote Paul Blank…

When the time came to replace the Traction Avant, the resulting auto could be expected to be absolutely remarkable – and it was.

The new auto, launched at the Paris Salon in 1955, was referred to as DS, which, when pronounced in French, is "Day-ess", which translates to Goddess. At the Paris Salon an amazing quantity of orders have been taken for the new vehicle – some 12,000 people signing on the dotted line.

In 1955 Australians had been purchasing new FJ Holdens and the Morris Minor was considered a modern day little vehicle in England. The DS may as well have been a spaceship in comparison. It certainly looked like

absolutely nothing else.

The automobile floated along at any speed. Famously, the DS featured Hydropneumatic suspension. It had the cars sitting on suspension units which have been steel spheres in location of classic springs and shock absorbers. The ride in a DS has to be knowledgeable to be believed. Even if a tyre blew, the car would compensate.

One more DS feature was the use of disc brakes. It was Citroen which very first fitted them to a mass-production vehicle.

Inside, the DS was as spectacularly bold as the rest of the auto. In an era of flat tin or wood dashboards, Citroen used the largest single piece of moulded plastic in the world. The DS in not a complex automobile just quite various.

You know the car’s prepared when very first the back, then the front of the automobile lift up to standard ride height. To modify gear, you lift off, switch to the next gear and accelerate away again. Then you have to discover about the brakes. Exactly where you may count on a brake pedal, there’s a black rubber mushroom. It operates like a valve operating by the "the tougher you push, the far more you stop" method, with virtually no pedal travel offered.

The DS isn’t a sports car it is a genuine Grand Tourer and, treated as such, offers a magical expertise.

SPECIFICATIONS

Citroen DS23 Pallas

Quantity constructed: 582,593 (All ID/DS 1968-75)

Body: All-steel, integrated physique/chassis four-door sedan and station wagon

Engine: 2347cc inline four-cylinder, OHV, 8v, fuel injection

Power & torque: 105kW @ 5500rpm, 200Nm @ 4000rpm

Performance: -97km/h 10.2sec -400m 17.3sec

Transmission: 3-speed automatic, 5-speed manual

Suspension: Independent with wishbones, pneumatic struts and anti-roll bar (f) Independent with trailing arms, pneumatic struts and anti-roll bar (r)

Brakes: Discs, power-assisted

Tyres: 185HR15 radial

Value range: 00-,000

Contact: Citroen Clubs in a variety of states,

www.ds23.co.nz/

Click right here for more automobile pictures at my Flickr web site.

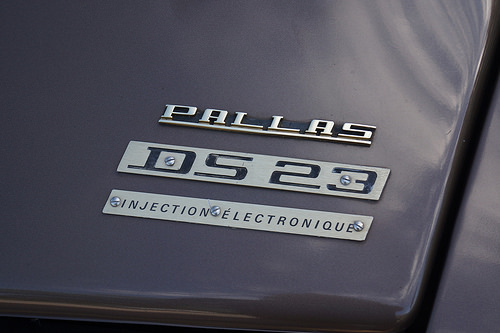

1973 Citroen DS23 Pallas

Image by DVS1mn

CITROEN DS23 PALLAS

When in 1955 Citroen released its DS19 ‘Goddess’, media commentators reviewed the vehicle in tones previously reserved for objects arriving from the depths of outer space.

Hydro-pneumatic suspension, help systems for the steering, brakes and gearshift lever, and inboard front disc brakes were amongst the advances pioneered by this extraordinary design and style.

By 1968 the rest of the planet had begun adopting elements of Citroen’s radical package nevertheless, Citroen wasn’t completed exploring the range of quirks it could pack into a medium-sized sedan. One new feature to perplex the residence mechanic was a link that would swivel headlights in unison with the front wheels.

The car’s potential to traverse rough terrain was proved in 1969 when a Citroen was set to win the very first London-Sydney Marathon, only to be taken out in a significant collision with a spectator car. Five years later, the Australian crew of a DS23 got the job done, dominating a 1974 Planet Cup Rally that sent competitors from South America to Munich by way of the Sahara Desert.

Maintaining a DS is perform for specialist technicians or maybe the seriously talented amateur. There is barely area beneath the bonnet of a Pallas to see engine elements, let alone place a spanner on them.

3-speed automatics were plagued by issues and remain difficult to preserve, so get a 5-speed manual if you can. Overseas values are offering a huge hint that any individual who wants a really excellent Pallas needs to act quickly. Be prepared to invest the far better part of ,000. Of many thousand automobiles sold new in Britain, fewer than 300 are identified to survive and numbers in Australia will be far slimmer.

TRAPS AND Suggestions

Packing a mass of electro/mechanical/hydraulic bits plus the complete drivetrain into a small space ahead of the firewall didn’t aid Citroen’s reputation for reliability.

Keeping your Citroen cool is vital to engine longevity and that can be pricey. A single spare components website was quoting authentic but renovated radiators at a lot more than 00. Replacing the coolant hoses with a set of genuine products will cost a lot more than .

Citroen club web sites of late have carried requests for assist in locating a competent trimmer for DS models. This suggests that finding a person to repair a car with worn seats and compromised head-lining has turn into challenging.

FROM THE WHEELS ARCHIVES

Words: Paul Blank – January, 2005

The DS was spectacularly bold, wrote Paul Blank…

When the time came to replace the Traction Avant, the resulting automobile could be expected to be absolutely remarkable – and it was.

The new auto, launched at the Paris Salon in 1955, was named DS, which, when pronounced in French, is "Day-ess", which translates to Goddess. At the Paris Salon an wonderful number of orders have been taken for the new automobile – some 12,000 men and women signing on the dotted line.

In 1955 Australians have been purchasing new FJ Holdens and the Morris Minor was regarded a modern day small auto in England. The DS may as well have been a spaceship in comparison. It certainly looked like

nothing else.

The auto floated along at any speed. Famously, the DS featured Hydropneumatic suspension. It had the vehicles sitting on suspension units which were steel spheres in spot of standard springs and shock absorbers. The ride in a DS has to be knowledgeable to be believed. Even if a tyre blew, the auto would compensate.

Yet another DS feature was the use of disc brakes. It was Citroen which initial fitted them to a mass-production automobile.

Inside, the DS was as spectacularly bold as the rest of the car. In an era of flat tin or wood dashboards, Citroen used the greatest single piece of moulded plastic in the planet. The DS in not a complicated auto just really diverse.

You know the car’s ready when 1st the back, then the front of the car lift up to typical ride height. To change gear, you lift off, switch to the subsequent gear and accelerate away once again. Then you have to understand about the brakes. Exactly where you may count on a brake pedal, there’s a black rubber mushroom. It works like a valve operating by the "the tougher you push, the much more you stop" program, with virtually no pedal travel accessible.

The DS is not a sports automobile it is a actual Grand Tourer and, treated as such, gives a magical knowledge.

SPECIFICATIONS

Citroen DS23 Pallas

Number built: 582,593 (All ID/DS 1968-75)

Physique: All-steel, integrated body/chassis four-door sedan and station wagon

Engine: 2347cc inline 4-cylinder, OHV, 8v, fuel injection

Power & torque: 105kW @ 5500rpm, 200Nm @ 4000rpm

Functionality: -97km/h 10.2sec -400m 17.3sec

Transmission: 3-speed automatic, 5-speed manual

Suspension: Independent with wishbones, pneumatic struts and anti-roll bar (f) Independent with trailing arms, pneumatic struts and anti-roll bar (r)

Brakes: Discs, energy-assisted

Tyres: 185HR15 radial

Value range: 00-,000

Contact: Citroen Clubs in different states,

www.ds23.co.nz/

Click right here for far more auto photos at my Flickr site.

Automotive Parts Moulding Available at Ease for OEMs

Automotive components moulding is a method by which spare components and accessories for automobile parts are manufactured and supplied to the automotive manufactures. Auto mould is generally a generic and holistic term for all the components of moulds that manufactured for vehicles. All kinds of moulds that are utilized in automobiles are known as auto moulds or automotive components mould.

Some major examples of auto moulds contain injection dies, injection moulds, stamping dies, forging dies, casting wax and glass moulds. There are numerous other parts in which auto moulds for the automobile manufactures are needed. This also holds the fact that all. All automotive stamping dies are also termed as the “automotive stamping dies.” Further to this auto moulds are also punching die are stamped on all kinds of automobiles.

Of course auto moulds are a specific series of plastic moulds that have application in vehicles. They are made and made as per the requirement of the automobiles panel dies, gages, assembly and welding fixing that has applications in the de4velopment of a sturdy body for the automobile

They form a special series of plastic moulds which are developed for certain purposes such as the following-

Auto interior or exterior parts -auto moulds are available to fulfil a full range of trim components for both the exterior and interior of the body of the car.

Vehicle Light Moulds created with strict top quality requirements with distinct sorts of plastic variants as per the specifications.

Other plastic components- other important parts of the auto moulds loved ones type the auto bumpers, instrument panels, inside door panels, door slip, rear view mirror, scratch rain, wheel cover, tank, shroud, fan etc. are also effortlessly accessible.

Auto lamp moulds – these are one more type of parts accessible to be provided to OEM as plastic automobile lamp moulds which are a specific category automotive moulds.

It is achievable to effortlessly procure these parts online as they supply chain procedure for OEMs have turn out to be genuinely feasible. The parts are accessible of highest top quality requirements and straightforward discounts from the web sites. They are created with the common procedures and technical capabilities of the workers. They are not only accessible to provide you the essential goods but also the preferred variety of specification for a certain automobile.

The most simple kind of moulds is plastic moulds that locate their applications in all sorts of purposes. The plastic moulds are also employed in creating the automotive moulds and other parts use in the car physique. They are obtainable in various configurations and well fitted for the most auto makers for distinct types of models. They are obtainable on-line and could be shipped in bulk to the supplier.

What is Injection Moulding China

A mould is a device that is utilised to make plastic items to be formed entirely and have precise dimensions. A good number of businesses around the globe obtain Injection Moulding China produced moulds. Some of these organizations make extremely enormous purchases and several of them have already set up obtain offices in China. This is due to the fact that the moulds are of high high quality and are sold at low rates.

Injection Moulding China moulds are of high high quality which evaluate really properly with moulds from countries such as America, Britain and other European nations. These moulds from China fetch competitive rates in the industry and this has produced other makers shed their market share to China. Injection Moulding China mould producing is a enterprise that is expanding by day. Most of the producers guarantee that they employ technical sales representatives who have a good command of the English language. For an injection moulding project to operate nicely, technical knowhow is the a single extremely substantial thing that is essential.

Injection Moulding China moulds projects are carried out making use of drawings that are sent by engineers from getting organizations. The drawing is generally scrutinized on how the mould shall be made in terms of material, formation, dimension and expense cutting. Buyer satisfaction is the essential right here and so the manufacturer guarantees that all the client needs regarding the mould formation are met to the letter. Most of the Injection Moulding China businesses have their own tooling plants, and as a result they are capable of generating high quality moulds for export to European businesses including America, Germany, Italy, Canada and numerous other nations. They employ mould engineers who are conversant with mould technologies and can communication in English with the consumers.

The Injection Moulding China businesses manufacture higher quality moulds that compete with American produced but at Chinese prices, which means rates that are really low. They make certain that they give you a competitive quotation following reviewing your specifications. The companies have a repute of manufacturing the appropriate moulds for the best price tag and they assure their perform.

To get the greatest out of Injection Moulding China created moulds, you need to have to look at references from businesses that have currently worked with them. You can by no means go wrong with moulds that are manufactured by leading rated mould creating firms in China. Look no additional come to Injection Moulding China businesses for all your injection mould requirements. You will get quite special moulds with no regrets at all!