The discharge framework is generally situated on the moving side of the form alongside the shape centers. Since ejector pins and different segments contact the trim, they leave observer marks on the adjoining surfaces, which can

■reduce the visual nature of the trim’s surface,

■interfere with mating gathering surfaces, and

■reduce quality in auxiliary applications.

Thusly, ejector pins and different parts ought to be found and intended to minimally affect the trim’s surfaces.

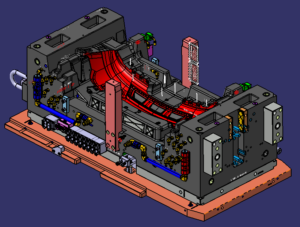

The most widely recognized methodology is to find ejector pins on non-visible surfaces and in low pressure regions of the embellishment. On the other hand, bigger parts, for example, sleeves, slides, lifters, and stripper plates might be deliberately utilized by high precision molds china with the end goal that their observer lines correspond with highlights of the trim. These deliberately planned segments can leave no evident observer line while giving successful launch across enormous territories of the part surface.

A few applications require one side of the trim to be totally liberated from all observer marks. In these applications, one technique in form configuration is to find the whole framework on the fixed side of the shape alongside the feed framework. This “opposite discharge” plan permits the outside of the moldings confronting the moving side of the shape to be totally liberated from witness stamps because of both the feed framework and the launch framework. This plan will be examined in more detail.

The expense of the discharge framework can be either an irrelevant or a huge part of the all out shape cost. The least complex molds utilize a tradable arrangement of ejector sticks, each with a similar measurement and length; such a plan follows plan for assembling and gathering rules [1] for part compatibility to limit the shape get together time and support necessities. Notwithstanding, most shape utilize various distinctive ejector pins with differing measurement, segment, and length. While the expense of extra expense of the pins is little contrasted with the expense of the mold, the mold designer of oem/odm industrial mold factory and form producer ought to make certain to key and name every ejector pin so they can be promptly kept up by the decay.

The expense of the ejector framework can increment significantly with the utilization of slides, lifters, and other launch sub gatherings. Once more, the objective of the shape planner is to give a basic, savvy, and solid plan that fulfills the recently depicted targets. The shape architect ought not simply think about the underlying plan and tooling costs, however the operational, support, and disappointment costs too.

The ejector framework configuration of china automobile molds factory is resolved first by the necessary format of the shape’s splitting surfaces, and accordingly by the definite plan of the different parts needed to discharge the molding(s). The accompanying plan measure accepts that the formed part of china custom mold components has been appropriately planned with a base number of under-cuts, and so on Something else, the shape fashioner ought to return to the part configuration to disentangle the form’s discharge framework plan. This article is from http://www.automoldchina.com/