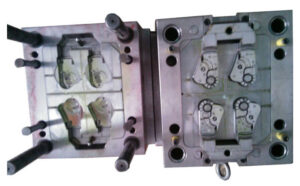

The capacity of a stripper plate is like that of an ejector sleeve, in that both are normally used to push on a fringe of the shaped part. The plan of the stripper plate shifts essentially, in any case, since it regularly pushes on most or the entirety of the whole fringe of the formed part(s). Thus, the stripper plate has an altogether bigger territory than a solitary ejector sleeve and a totally unique development.

The compressive pressure in ejector cutting edges and the forced shear weight on the trim by the ejector sharp edges don’t for the most part oblige the plan of the ejector edges.

Because of their little thickness, notwithstanding, clasping can be a worry. Hence, the thickness of the ejector edge should approach the full thickness of the rib. The clasping is as yet represented by oem/odm automotives injection molding factory, however with the snapshot of latency characterized for a rectangular segment.

The capacity of an ejector sleeve is like that of an ejector sharp edge, in that both are commonly used to push on a vertical segment of the shaped part, The plan of the ejector sleeve shifts altogether, notwithstanding, since it is an empty chamber that slides along a fixed center pin to give a discharge power at the base surface of a formed chief. Ejector pinnacle sleeves are extremely compelling segments for part discharge, since they push on a firm managers in the part at an area where rubbing powers between the embellishment and the center happen.

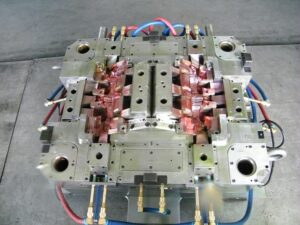

An average ejector sleeve get together plan is given in high precision plastic making mould suppliers china, In this plan, an exceptionally conductive center pin is situated in the back clasp plate and made sure about with an attachment head set screw. The center pin goes through the back brace plate, ejector plate, ejector retainer plate, uphold plate, and center addition to burrow out the ideal part of the shape pit, The ejector peak sleeve is held by the ejector retainer plate and goes through the help plate and center supplement. In the plan of detail A, the finish of the ejector sleeve is coplanar with the highest point of the chief and the nearby rib.

Given the annular math and enormous snapshot of idleness for ejector sleeves, there are normally no issues identified with pressure or clasping. Notwithstanding, the point by point plan of the ejector sleeve is particularly basic since it slides along between a fixed center pin and the fixed center supplement. The pivotal area of the ejector sleeve is administered by the concentric mating of the ejector sleeve with the ejector opening in the center addition. Since the center pin is inner to the sleeve, the divider thickness and concentricity of the trim around the center pin is represented by the resilience stack-up of the ejector opening, ejector sleeve, and center pin. To decrease dimensional varieties in the shaped part, clearances for venting should be limited.

oem mold factory give instances of clearances in the different form plates. The form fashioner ought to guarantee that the center pin has a reasonable freedom through the ejector plate and ejector retainer plate, in any case a slight absence of concentricity between the ejector sleeve and center pin may make the sleeve tie.

This article is from http://www.automoldchina.com/