When the cooling line distance across, profundity, and pitch have been resolved, the cooling lines can be steered through the form. This steering is of basic significance since it not just effects the expense and nature of the moldings, yet additionally restricts the position of other form segments, for example, ejector pins and jolts. By and large, the shape configuration ought to give at any rate a large portion of a cooling distance across between the outside of the cooling line and the outside of some other form part. This plan imperative is given to keep up the basic trustworthiness of the form while additionally limiting cooling spills during mold activity because of consumption. The concealed zone in Fig. 9.8 speaks to the potential areas in the form where cooling lines might be set.

While the concealed zone of Fig. 9.8 speaks to a huge segment of the shape, the arrangement of cooling lines is additionally obliged by possible obstruction with the form hole, hole embeds, center supplements, ejector return pins, direct pins, sprue bushing, and other shape parts. The past examination for the cup/top shape proposed that the cooling framework configuration use: a cooling line distance across of 6.35 mm, a cooling line profundity of 12.7 mm, and a cooling line pitch of 25.4 mm.

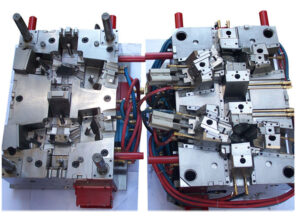

The plan actualized precisely to these proposals is appeared in injection mold company china. This underlying plan is infeasible for some reasons. Maybe the most noteworthy inadequacy in the plan is that a significant number of the cooling lines cross basic form highlights, for example, the sprue bushing or the interface between the pit embeds and the shape plates. There are two unique procedures to determine this issue. One methodology is to amplify the depression embed, center supplement, and related form plates to fit all the cooling lines inside the envelope of the center and pit embeds. This choice is exorbitant since it requires update of the shape, acquisition of a bigger form base, and all the more machining. Notwithstanding, such a plan might be financially legitimized given the more fast and uniform cooling.

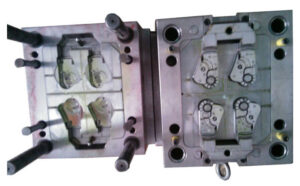

An elective methodology is to move the cooling lines further from the form depression while keeping up a similar pitch to profundity proportion for the Cooling lines. The subsequent plan is appeared in china industrial injection mold suppliers. This plan requires less Cooling lines, all of which stay away from the crossing point with other shape parts. While this plan gives helpless cooling execution, it is very normal. An essential favorable position is that the entirety of the cooling lines are straight, yet each C0oling line additionally goes through a solitary shape plate also. Accordingly, the C0oling lines can be machined in a solitary arrangement with no requirement for seals or gaskets. Shockingly, the position of the cooling lines a long way from the form pit will lessen the pace of warmth move and require longer process durations. The pace of warmth move is additionally diminished since the c0oling lines are put in another plate, and there will be a warm contact obstruction related with the warmth stream between the two plates [13].

There is a second critical inadequacy in cooling line format of china industrial injection moulding manufacturers, which originates from the utilization of a straight cooling line with a center of huge stature. The wellspring of cooling is the help plate behind the center addition, a long way from the warmth source beginning from the plastic dissolve in the depression. All things considered, critical temperature varieties will create all through the form and shaped part during cooling.

The anticipated temperature disseminations toward the finish of the trim cycle for the cup are given in Fig. 9.11, in which each shape line speaks to a 2°C change in temperature. Because of the generally profound center, an angle of 6°C exists from the base of the center to the head of the center. The temperature angle in pp joint fitting mould will drive differential shrinkage along the hub of the cup just as differential shrinkage through the divider thickness of the embellishment. The explanation is that the temperature at the head of the center isn’t just 6°C more sizzling than the temperature at the base of the center, but on the other hand is generally 6°C more sultry than the temperature at the contradicting surface on the cavity embed. Three choices for redressing the circumstance incorporate utilizing a profoundly conductive center addition, actualizing a confuse or bubbler, or planning a cooling embed. These distinctive cooling plans are next examined.

This article is from http://www.automoldchina.com/