The volumetric shrinkage compares to shrinkage in each of the three spatial components of the shaped part. On the off chance that a material displays similar properties toward each path, it is supposed to be “isotropic.” Most unfilled plastics show isotropic conduct, with the end goal that the properties of the shaped part are comparative in bearings corresponding to the heading of stream, opposite to the course of stream, and over the thickness.

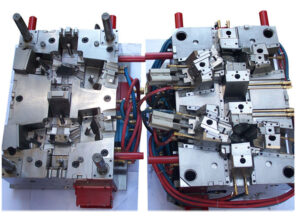

On the off chance that a material is isotropic, at that point it should show a similar straight shrinkages in china mould-building services, every which way. Consider a unit block and a contracted 3D shape as appeared in high precision plastic making mould china, in which the contracted block has a general change in the volumetric shrinkage of Fv Each side of the contracted 3D square has been decreased from L to L(1-s), where s is the direct shrinkage.

The volume of the unit shape is L3. The volume of the contracted solid shape is L3. ry, which to keep up protection of mass should likewise approach (L(1-S))3 subsequent to contracting. This prompts the condition. Register the straight shrinkage for the bezel formed in ABS. Expecting the past conditions, the general change in the volumetric shrinkage was 0.99 1%,This prompts the isotropic shrinkage of.

This shrinkage gauge is underneath the suggested shrinkage pace of 0.6% gave by the material provider. The distinction, which isn’t really a mistake, is likely because of the generally high pressing weight of 66 Mpa (9600 psi) that was expected for this slight divider application.

A few materials, for example, fluid gem polymers and glass filled polymers, show material properties that are a subject to the stream bearing. For these anisotropic materials, the particles or potentially filaments can turn out to be profoundly adjusted in the stream field during the filling and pressing stages as appeared in Fig. 10.6. As appeared by the viewpoint proportion and heading of the ovals, the direction through the thickness can be very intricate. The shear stream during the flling and pressing stages will in general arrange the plastic soften toward move through a considerable bit of the thickness.

Since glass has a lower coefficient of warm development, the material will likewise will in general have lower shrinkage in the stream bearing than in different ways. The connection among volumetric and anisotropic straight shrinkage is appeared in high precision plastic injection mould suppliers, where the variable a speaks to the part of anisotropy in the stream bearing identified with the other two headings.

Accept that an ABS is utilized by mould manufacturing factory to shape the bezel with 15 % glass fiber by weight. (Such a material exists for this application, known as Cycolac CRT3370.} Estimate the anisotropic shrinkage if the plastic material is referred to shrivel half as much in the stream bearing contrasted with different headings.

To begin with, the expansion of 15 % glass fiber will decrease the volumetric shrinkage since the glass has very lttle warm extension contrasted with the plastic. Since glass has a thickness of 2600 kg/m; and the unfilled or”neat” ABS has a thickness of 1040 kg/m3, the volume of the glass fiber in the ABS. The arrangement has united after two cycles. The shrinkage, s, approaches 0.35 % in the cross stream and thickness headings, and the shrinkage in the stream course, is 0.18%.

This article is from http://www.automoldchina.com