When the layout and lengths of the feed system have been resolved, the widths of each bit of the feed system ought to be resolved by china precision molds factory.

The progression of polymer soften through the feed system is in the laminar stream system. For china precision molds manufacturers to confirm laminar stream, the Reynolds number, Re, ought to be under 2300. Where is the volumetric stream rate (regularly on the request for 50,10 6 m3/s), .

Pmelt is the thickness (regularly on the request for 1000 kg/m}), met is the clear consistency (commonly on the request for 100 to 1000 Pa-s), and D is the sprinter measurement (ordinarily on the request for 0.01 m). Subbing average qualities for the factors in Eq.6.2 demonstrates that the Reynold’s number is on the request for 0.1. In that capacity, the stream system is a long way from violent, inertial impacts are immaterial, and the weight drop, AP, can be assessed utilizing the well-known Hagen Poiseuille condition. Where L and R are the length and span of a segment of the sprinter. To give a precise gauge of the weight drop utilizing the Newtonian model, the clear consistency ought to be assessed for the polymer soften at a proper shear rate.

For a force law liquid, the weight drop can be assessed straightforwardly without figuring of the shear rate.

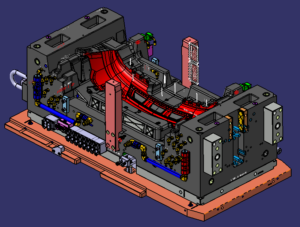

In the model of oem/odm injection mold factory, The investigation accept that ABS is formed with a volumetric stream rate at the gulf of 125 cc/s. To abstain from figuring the shear rate in each part of the sprinter, the force law model is utilized with k equivalent to 17 ,000 Pas/and n equivalent to 0.35.

The drag of the hot sprue bushing is 90 mm long and has a range of 6 mm. The volumetric stream rate through the hot sprue bushing is 125 cc/s, so the weight drop through the sprue.

After the hot sprue bushing, the liquefy branches into two stream streams. Since the multigated PC bezel is almost symmetric, the stream rate through every leg of the hot sprinter system is thought to be half of the delta stream rate, or 62.5 cc/s. Every leg of the complex is 1 18 mm long with a sweep of 5 mm, so the weight drop through the complex.

To ascertain the weight drop through the spout, the most exact gauge might be given by examining each fragment of the tightened bore. Given this specific spout bore math, be that as it may, a sensible gauge might be gotten by demonstrating the tightened bore as a consistent segment with a sweep of 3.5 mm and a length of 108 mm. The weight drop is then Once the weight drop through the feed system is investigated, it is conceivable to modify the feed system configuration to improve the presentation. Different emphases of plan and investigation might be led to get a plan that gives a low weight drop while expending almost no material. Multivariate enhancement is a mathematical method that could be utilized to at the same time limit the weight drop while limiting the sprinter volume. Nonetheless, this methodology expects time to actualize and approve while smothering the subtleties of the examination from the fashioner.

This article is from http://www.automoldchina.com/.