Nonetheless, homeowners who set up composite decking are often shocked to find out how their decking substances respond to climate changes when winter hits as compared to cedar wood.

Colour Transforming

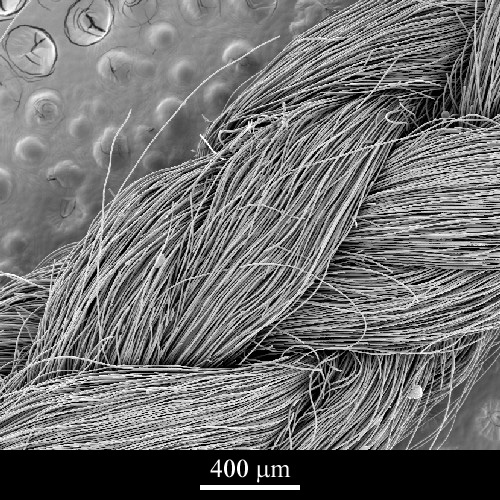

In theory, composite decking offers the extremely greatest of both worlds. The wood supplies aesthetics and strength, although the plastic gives protection against the components. In fact, while the plastic does protect the wood from sunlight damage and most moisture, it can’t regularly fully encapsulate each and every wood fibre. As an outcome, your deck may wind up with some wood fibres on the surface. These wood fibres can disappear when subjected to the components, and could rot away via time. All through winter months, some discoloration could be knowledgeable by a composite deck.

As technology and production procedures increase, discoloration and exposed wood have become less and significantly less of a difficulty nevertheless, it is something to know about. It is feasible for you to head off lots of the difficulties by meticulously selecting out a high quality composite deck maker.

Railcraft – top quality element of railing systems

There are a number of different possibilities in composite decking to pick from but when it comes to creating an investment on care-cost-free material then Railcraft aluminium railings is one particular fine alternative. They are very appreciable for their higher quality resistant to rot and rust. Even after you install them you do not want to repaint them. They are also known for minimizing material and labour upkeep cost.

Mould and Mildew Improvement

Numerous property owners who bought composite when it was comparatively new decking were shocked to find that following becoming subjected to winter rains, their decks showed indications of mildew and mould improvement.

Numerous producers add the decking material to help in stopping the development of fungus and mould inhibitors. In addition, the most effective protection against mildew and mould is routine cleaning. Be confident that your deck planks have appropriate spacing and eliminate any potted plants out of your deck as water can pool beneath them throughout winter and give a breeding ground for mildew and mould.

If mildew and mould development does take place, it is important to manage the dilemma promptly to avert harm or any added staining. Adhere to the maker’s suggestions, if you are making use of a deck cleaner.

Make use of spray and a fan tip nozzle collectively with the wood’s grain design and style. An excessive quantity of stress is not a very good point for the decking material, so guarantee not to go over the recommended maximum stress. Furthermore, take the appropriate security precautions when managing any gear.