China mould design services has tried to give a designing way to deal with mold plan; the accentuation has been on the assessment and displaying of essential components that oversee the utilization and disappointment of infusion molds. The models have deliberately been made as basic and clear as possible conceivable, so the specialist can apply the plan and examination strategies to more explicit and progressed shaping applications.

There are many progressed forming measure advances that give key benefits on an application explicit premise. Most developed embellishment measures require explicit form plans. A stream graph has been given in oem/odm automatives injection overmould factory to direct the choice of some of accessible mold advancements. Such mold advancements can be utilized to contend viably by furnishing formed parts with better caliber in less time and at lower costs. The majority of these advancements have been created for explicit purposes, for example, to deliver a formed part with novel properties, or to all the more financially produce enormous amounts of molded parts.

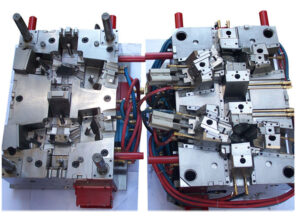

Many embellishment advances are entwined. For example, multi-shot forming (in which a molded part is made of at least two materials) has attributes that are identified with co-injection shaping, embed shaping, stack shaping, and even infusion blow shaping. Despite the degree of innovation, the hidden physical science and mold plan essentials that have been recently given actually apply. All things considered, this part gives an outline of some accessible trim innovations, and examines related form configuration issues. Instances of illustrative mold plans have been sourced from the U.S. patent writing. The goal here isn’t to give a thorough study of mold related advances, or even to suggest explicit form plans. Maybe, the purpose is to show some fascinating models that will permeate the professional with explicit bits of knowledge into a scope of form advances so they may turn out to be better mold creators.

In applications, mold and item originators ought to examine the fuse of form advances as a feature of an assembling system to either build client’s readiness to pay [1] or lessen costs. Breakeven investigation, for example, introduced in Section 3.4, can be utilized by injection molding service china to help the suitability of various form advances.

Molds are mechanical gatherings that should withstand significant degrees of stresses forced by the pressing factor of the polymer dissolve. A few limitations drive the foundational layout of the form. In the first place, the form should be intended to try not to yield given a solitary over-pressure circumstance. Second, the mold should be intended to maintain a strategic distance from disappointment because of weariness related with the cyclic burdens related with embellishment thousands or millions of cycles. Third, the form should be intended to stay away from inordinate avoidance while shaping, which would prompt blazing of the formed parts and sped up wear on the form’s splitting line. Of these issues, weakness and avoidance will in general overwhelm however the overall significance is an element of the quantity of form pits, the trim pressing factors, the mold calculation, and the creation amount.

Examinations were given to display the pressure of form plates, centers, and backing columns just as the bowing of plates, side dividers, and centers. Superposition of pressure and bowing can be utilized to assess the all out diversion of the depression surfaces. Examinations were likewise produced for pressure focuses in mold plates. As a rule, all examinations show that expanding the measure of steel between the heap and backing focuses accommodates lower levels of pressure and avoidance. Accordingly, the form architect should perform examination to create hearty plans that are not uneconomical. The employments of help columns, interlocks, and different plans were shown to decrease diversion. This article is from http://www.automoldchina.com/